A method of connecting a rotary encoder to a PLC

A method of connecting a rotary encoder to a PLC

NPN open collector output

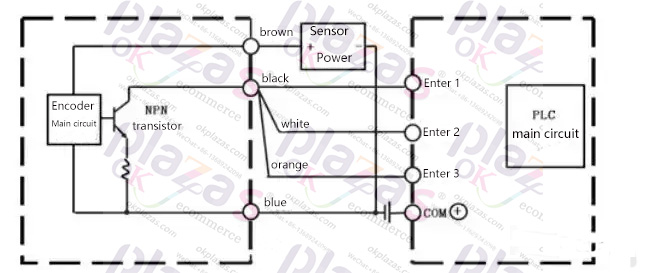

Method 1: As shown below

This wiring method is used when the sensor's working voltage is different from the PLC's input voltage, take the encoder transistor part, and connect it to the power supply in series to connect to the PLC in a non-voltage form. But it should be noted that the voltage of the external power supply must be below DC30V, and the switching capacity is below 35mA per phase. If the working voltage is exceeded, the encoder may be damaged.

The specific wiring method is as follows: the brown wire of the encoder is connected to the positive electrode of the encoder working voltage, the blue wire is connected to the negative electrode of the encoder working voltage, the output wire is connected to the input point of the PLC in turn, the blue wire is connected to the negative electrode of the external power supply, and the positive electrode of the external power supply is connected to the PLC. Enter the com terminal.

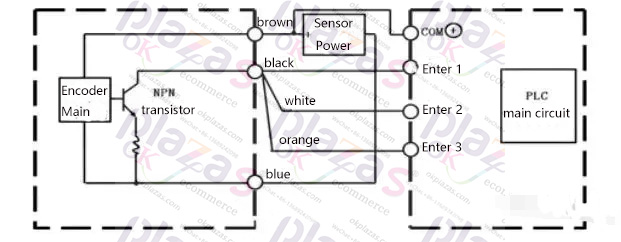

Method 2:

The brown wire of the encoder is connected to the positive pole of the power supply, the output wire is connected to the input point of the PLC in turn, the blue wire is connected to the negative pole of the power supply, and then a wire from the positive end of the power supply is connected to the PLC input com terminal.

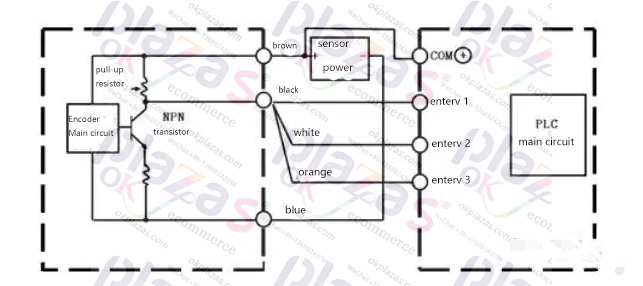

The voltage output wiring mode is shown in the figure

The specific wiring method is as follows: the brown wire of the encoder is connected to the positive pole of the power supply, the output wire is connected to the input point of the PLC in turn, the blue wire is connected to the negative pole of the power supply, and then a wire from the positive end of the power supply is connected to the PLC input com terminal.

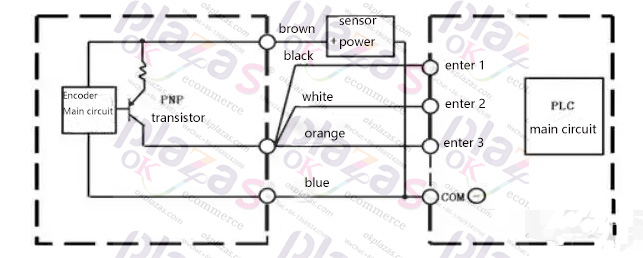

The wiring method of PNP open collector output is shown in the figure below

The specific wiring method is as follows: the brown wire of the encoder is connected to the positive electrode of the working voltage, the blue wire is connected to the negative electrode of the working voltage, the output wire is connected to the input com end of the PLC in turn, and then a wire is connected from the negative end of the power supply to the input com end of the PLC.

The specific wiring of the linear drive output is as follows

The output wires are connected to the corresponding input points of the subsequent equipment in turn, the brown wire is connected to the positive electrode of the working voltage, and the blue wire is connected to the negative electrode of the working voltage.