Common problems and avoidance methods of Schneider molded case circuit breakers

Common problems and avoidance methods of Schneider molded case circuit breakers

Common problems and avoidance methods of Schneider molded case circuit breakers

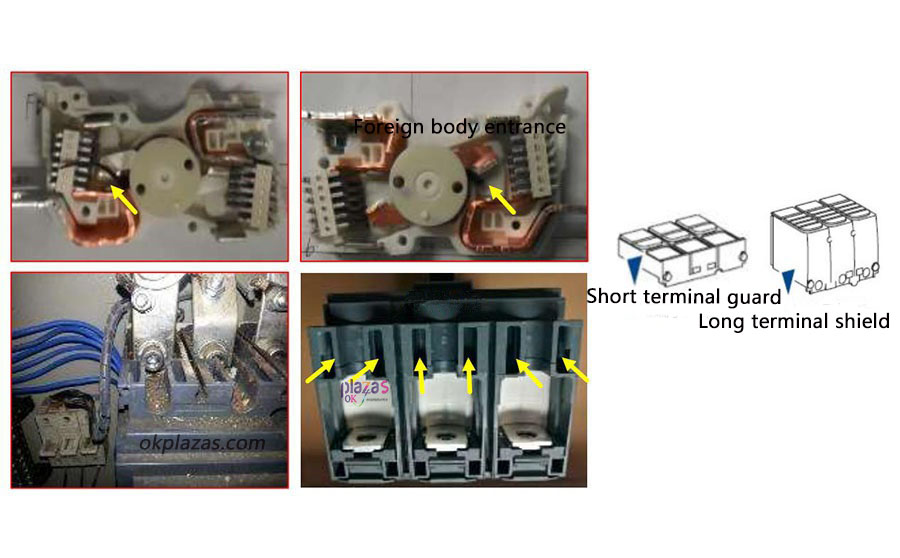

Fault description: A foreign body enters the device and causes phase loss.

Cause: When installing the Schneider molded case circuit breaker, some foreign objects fell into the interior, which caused the equipment's moving and static contacts to have bad phenomena when they were in contact and even lack phase.

Avoidance method: ◆It is recommended to install a terminal sheath, so that it can greatly prevent direct contact with the busbar both in use and maintenance, and at the same time can increase the IP protection level.

Fault description: Large current arc spraying causes the equipment to lose phase.

Cause:

1. Mistakes occurred during the selection of Schneider molded case circuit breakers (that is, unreasonable and inconsistent with actual application requirements, such as using distribution type circuit breakers in motor protection).

2. A short circuit between phases is like a metal object lapped in a two-phase circuit.

Avoid method:

◆It is recommended to use phase spacers, which can effectively improve the insulation protection level of the circuit breaker between phases.

◆Before powering on, it is recommended to check whether there are foreign objects in the line to ensure that it is clean and tidy.

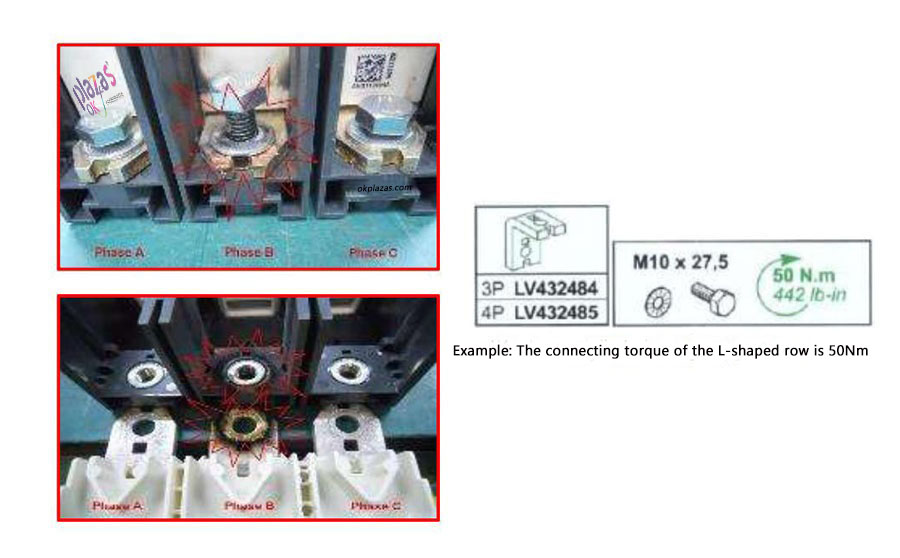

Fault description: The terminal screw is not tightened, causing burns.

Cause: During installation, the screw tightening torque is insufficient, resulting in a virtual connection and burning.

Avoidance method: ◆It is recommended to refer to the instruction manual of Schneider circuit breaker, which is usually equipped in the package.

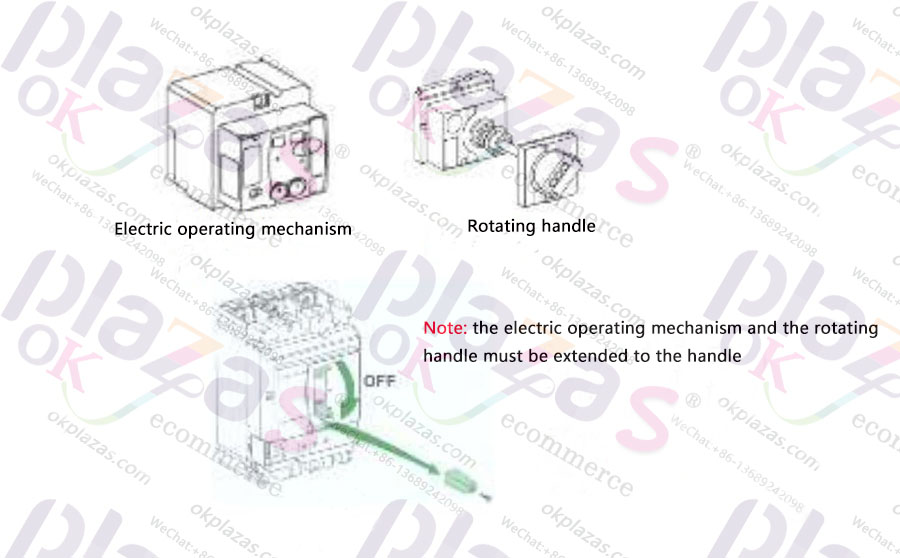

Fault description: The handle of the circuit breaker is deformed or broken.

Cause: Use improper tools to pull the handle.

Avoidance: ◆It is recommended to use the rotating handle and electric operating mechanism provided by Schneider, so as to prevent the deformation and fracture of the handle from occurring.

Fault description: Schneider molded case circuit breaker terminal screw overflow.

Cause: Use non-Schneider standard nuts.

Avoidance method: ◆It is recommended to use Schneider standard nuts and install according to the tightening torque requirements in the manual. For example, the connection torque of the NSX100 type copper bar is 10Nm, and the connection torque of the NSX160/250 type copper bar is 15Nm.

Fault description: The breaker base is damaged.

Cause: Use of non-Schneider standard screws for installation, causing failures such as slippage of the screws and short circuit to the ground.

Avoidance: ◆It is recommended to use Schneider standard screws and nuts, and install according to the tightening torque requirements in the manual.

Fault description: Schneider molded case circuit breaker handle mechanism shunt excitation, undervoltage coil reset rod deformed.

Cause: NSX/CVS/EZD400-630 and other series models did not install the coil in the trip position, or did not install the trip button first when installing the MNMX coil.

Avoidance: ◆It is recommended that the handle mechanism be in the trip position when installing the coil, and at the same time press the trip button before installing the coil.

Fault description: The shunt and undervoltage coil of the molded case circuit breaker is damaged.

Cause: Improper installation of the coil will cause

1. The MNMX reset rod is broken;

2. The spring is not hung on the hook;

3. The base support plate falls off;

4. The reset rod connecting rod is broken;

5. Screw sliding teeth.

Avoid method: ◆It is recommended to refer to the correct installation video to control the operation.

Fault description: Rotate the handle extension rod to fix the top wire overflow buckle.

Cause: Excessive installation torque of the jack screw will cause the screw to overflow, and the installation of incorrect tools will cause the hexagonal thread in the jack screw.

Avoidance method: ◆It is recommended to use 2.5mm hexagonal wrench and the installation torque is 1Nm.

Fault description: The rotating handle panel cannot be fixed.

Cause: The tightening torque of the panel mounting screws of the plastic case circuit breaker's rotating handle is too large, causing damage to the handle fixing frame.

Avoidance: ◆It is recommended to use a Phillips screwdriver and the installation torque is 1Nm.

Fault description: The white connecting rod in the safety trip lever is broken.

Cause: The white connecting rod was incorrectly installed in the plug-in or withdrawable Schneider plastic case circuit breaker and was damaged.

Avoidance: ◆It is recommended that the white connecting rod is only suitable for the assembly of dual power supplies. It is used in the base plate interlocking. The plug-in and withdrawable types do not need to install this connecting rod.

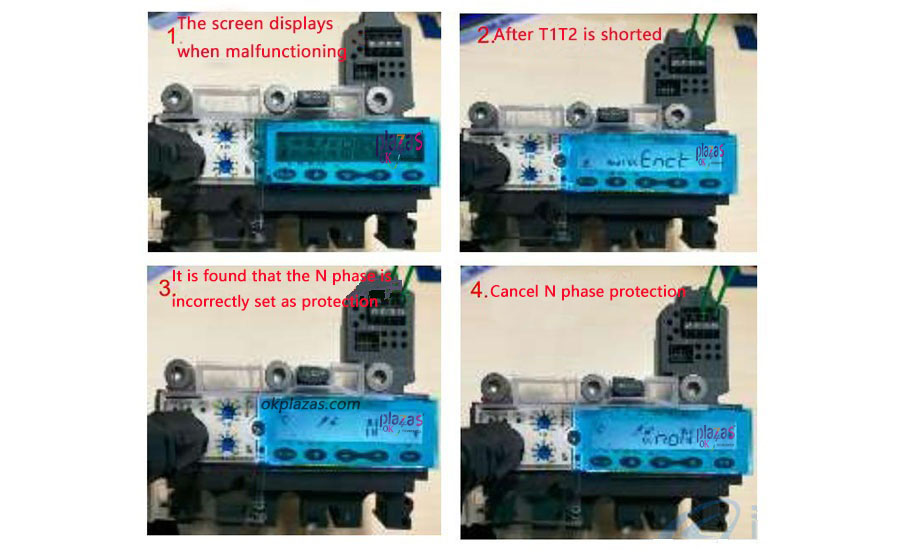

Fault description: The multifunctional electronic trip unit malfunctions.

Cause: The 3-pole molded case circuit breaker with multi-function electronic trip is set to N-pole protection by mistake.

Avoid method: ◆It is recommended to refer to the following methods to restore the default settings

1. The device screen jumps, and the trip unit cannot be reset;

2. Short-circuit T1 and T2;

3. Unlock the screen, the screen displays the N phase setting as protection;

4.Cancel the N-phase protection by adjusting the button.

Fault description: LTU software cannot connect.

Cause: The LTU software version upgrade caused the normal connection to fail.

Avoidance: ◆It is recommended that if an abnormal connection is found, it may be caused by a low test version, so the normal connection can be restored by upgrading the software. First open the LTU software and check whether the software version number is the latest version through Help→About. If it is not, select the LTU software Update to upgrade after the computer is connected to the Internet, and then upgrade to the latest version.

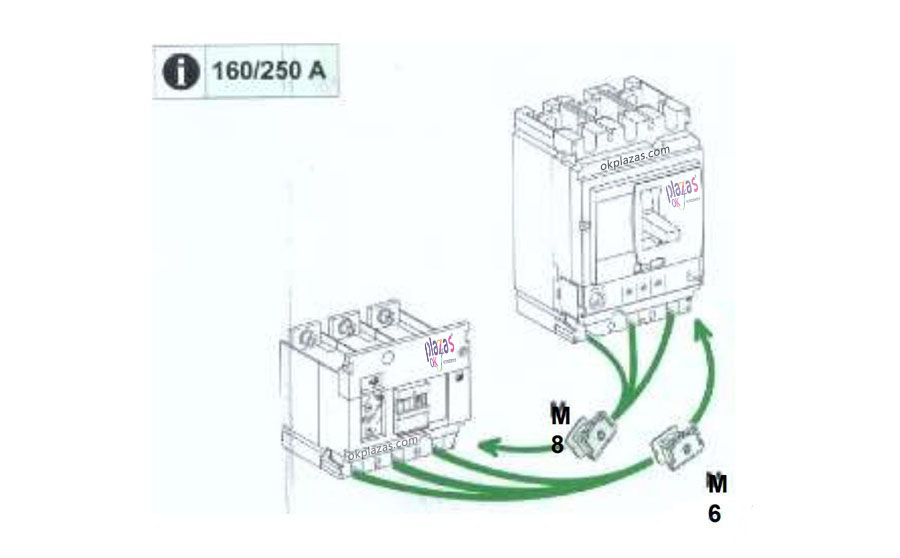

Fault description: The leakage module cannot be installed on the 160-250A molded case circuit breaker.

Cause: The screw of the leakage module is M6 specification, and the nut of 160-250A is M8 specification, so it cannot be installed.

Avoidance method: ◆It is recommended to exchange the terminal nut at the emergence end of the circuit breaker and the terminal nut at the outlet end of the leakage module. After the exchange, it can be connected normally.

Fault description: The leakage module does not work.

Cause: The short circuit board in the upper cover of the leakage module is damaged.

Avoidance method: ◆It is recommended to prevent the shorting board from being touched during installation, which may cause damage to the shorting board. If it is found to be damaged, it should be replaced immediately.

Fault description: The housing of the motor operating mechanism cannot be fixed.

Cause: The screw tightening torque is too large and the nut falls off.

Avoidance method: ◆It is recommended to pay attention to the electric operating mechanism and Schneider molded case circuit breaker when installing to the energy storage position. The electric operation panel indicates: O FF, Charge position, and the upper cover installation torque is 1.5Nm.

okplazas.com is a professional sales agent for Schneider Electric products. Welcome to email: [email protected] for consultation, and you can also contact WeChat +86-13689242098 online customer service for product consultation!