Displacement sensor manufacturer, Xi'an displacement sensor

Displacement sensor manufacturer, Xi'an displacement sensor

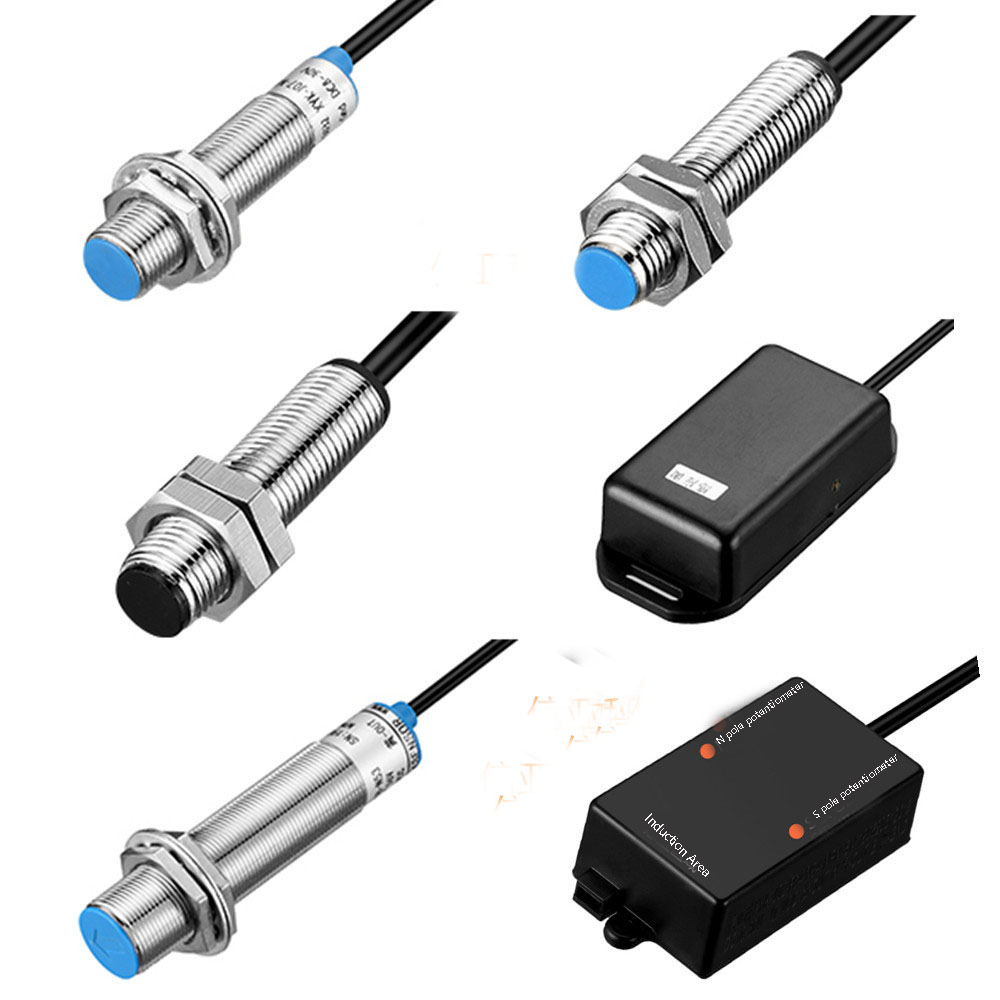

The function of the displacement sensor is to convert various measured physical quantities into electricity. In the production process, measuring displacement is generally divided into measuring physical size and mechanical displacement. Displacement sensors are widely used in all walks of life due to their high precision and high reliability.

Displacement sensor application solutions:

1. Plastic and rubber injection molding machine

Measure the displacement of four main movements: loading, injection, die opening/closing, and withdrawal.

2. Film blowing machine

Measure the open/close displacement of the die, the translation of the die, and check the prototype.

3. Material processing

Measure the displacement of tools such as brushes, wheels or rollers used in metal, wood, marble and ceramic processing.

Fourth, hydraulic cylinders and air cylinders

Check the displacement of the piston-the sensor is located inside, and the magnetic ring cursor is fixed on the piston to track its movement.

5. Geological technology

Sensors used for settlement gauges and strain gauges used to monitor the structure-preferably cylindrical models.

6. Test equipment for the automobile industry

Tuning of the cantilever system of prototype and competing models. Test bench, racing car.

7. Farm and earth moving machinery

Check the position of the robot arm, the inclination of the bucket, the height from the ground, the crusher, and determine the size of the asphalt processing machine.

8. Food Industry

Check the amount of the dispensed substance by filling the buzzer or other injection molding machine.

9. Renewable energy

Check the sun tracking position, check the slope of the wind engine, check the valves and partition walls of the hydropower plant.

10. Liquid level check:

Measure the liquid level in the tank by selecting the buoy