How is the technical performance on the KTR coupling table

How is the technical performance on the KTR coupling table

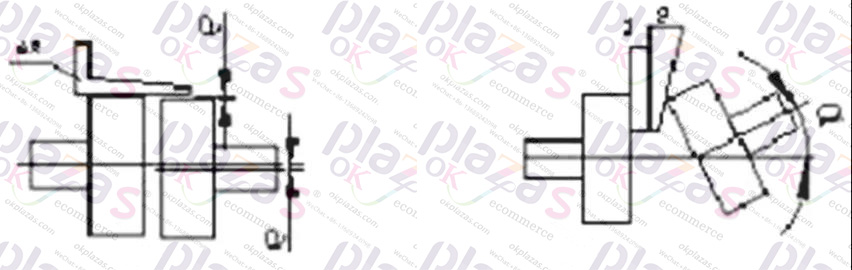

KTR coupling, also known as coupling, refers to a device that connects two shafts or shafts and rotating parts, and rotates together in the process of transmitting motion and power, and does not disengage under normal conditions. Sometimes it is also used as a safety device to prevent the connected parts from being subjected to excessive loads and play a role in overload protection.

Couplings are widely used in the air compressor industry, especially in direct-coupled air compressors. The electric power must be transmitted to the head of the air compressor through the coupling. It is one of the indispensable and important accessories.

KTR coupling type characteristics

Types of

Commonly used precision couplings are: elastic couplings, diaphragm couplings, bellows

Couplings, sliding block couplings, plum blossom couplings, rigid couplings.

Features

1. Flexible coupling

(1) One-piece metal elastomer

(2) Zero backlash, synchronous operation

(3) Elastic action compensates radial, angular and axial deviations

(4) High torque rigidity and sensitivity

(5) Clockwise and counterclockwise rotation characteristics are exactly the same

(6) Maintenance-free, oil and corrosion resistance

(7) There are aluminum alloy and stainless steel materials for choice

(8) There are two main fixing methods: top wire and clamping.