How to learn Mitsubishi positioning control

How to learn Mitsubishi positioning control

If your work is mainly applied to positioning control, then choose to learn the content of positioning control first. If you choose to learn the content of positioning control in the follow-up, then you need to learn the basic knowledge of positioning control, pulse output and positioning control instructions, and the preparation of control programs.

Mitsubishi FX series PLC positioning control technology mainly includes positioning control introduction, FX series PLC positioning control functions, pulse output and positioning instructions, encoder introduction, pulse equivalent and electronic gear ratio settings, positioning control operation mode analysis, linkage and interpolation analysis. PLC positioning and servo control system, FX3U PLC positioning control instructions, servo drive parameter settings, etc.

After learning the above content, you will be able to achieve the following goals: 1. Master the basic knowledge of positioning control and positioning control instructions. 2. Master the positioning control application of Mitsubishi FX series PLC. 3. Ability to independently write positioning control applications. 4. Master the parameter settings of the servo drive, and how to connect the PLC and the servo drive, cooperate with each other to realize the positioning control function.

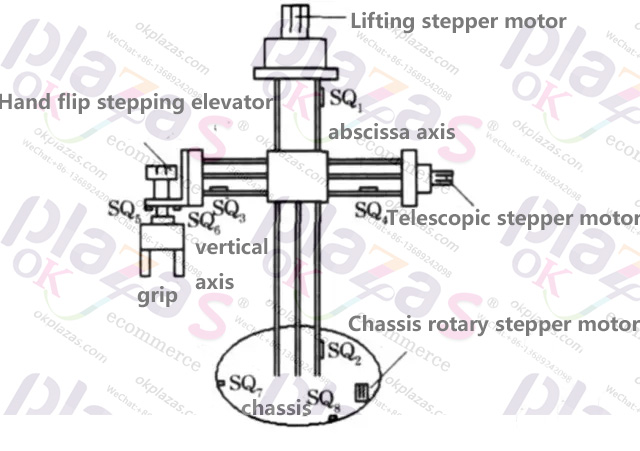

At this stage, you can independently write simple positioning control programs. For example: forward and reverse control, fixed-length cutting, fixed-point machining, elevator positioning control, dual-axis (X-axis and Y-axis) positioning control, single-speed positioning reciprocating operation, dual-speed positioning motion, dual-axis positioning manipulator control, etc. Master the positioning control application of Mitsubishi FX series PLC. You can write positioning control applications independently, set the parameters of the servo drive, and do some positioning control projects. At this time, your boss will look at you differently, and the salary level will be different. There is a substantial improvement.

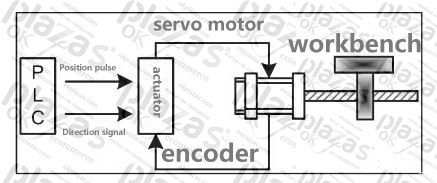

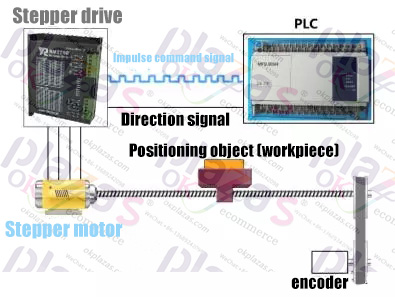

For the learning of Mitsubishi FX series PLC positioning control technology, the first thing is to learn the basic knowledge of positioning control, including positioning control and positioning control mode introduction, positioning control pulse output mode (pulse + direction control, forward and reverse pulse control, bi-phase AB pulse Control, differential line drive pulse control), the composition of the PLC positioning control system (controller, driver, motor), etc.

After learning the basic knowledge of positioning control, you also need to learn FX PLC positioning control modules and dedicated units, including the positioning control functions of various types of FX-PLC PLC (FX1S, FX1N, FX2N, FX3U), positioning control module (FX2N-1PG) , FX2N-10PG), positioning control unit (FX2N-10GM, FX2N-20GM and other positioning control units), special adapter expansion unit.

In addition, you must learn the content of the encoder, including the introduction of the encoder, the classification of the encoder (incremental and absolute encoder), the use and application of the incremental encoder, and the focus on the learning of the encoder Quantitative encoder; also learn pulse equivalent and electronic gear ratio settings, including the concept of pulse equivalent, electronic gear and electronic gear ratio, electronic gear ratio application and settings, and calculations in positioning control.

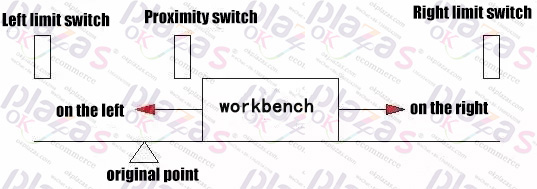

There is also the learning of PLC positioning instructions, which is also very important. You need to learn relative positioning, absolute positioning, origin (mechanical origin, electrical origin), zero (mechanical zero, electrical zero); learn the relevant parameters of positioning control, including Origin return speed and crawl speed, maximum speed and base speed, motor operating speed, acceleration time and deceleration time, etc.; learning speed and time parameter settings, positioning control operating position, operating position current value register; and learning positioning control instructions, including Relative positioning instructions, absolute positioning instructions, origin return instructions, DOG search origin return instructions, interrupt positioning instructions, table positioning instructions, etc.

In addition, you also need to learn the analysis of various positioning modes, including origin regression mode analysis, DOG block signal origin return structure, zero-phase signal counting origin return, origin return search function; learn single-speed fixed-length operation mode analysis , Single-speed manual (JOG) operation mode analysis, interrupted single-speed fixed-length operation mode analysis, interrupted two-speed fixed-length operation mode analysis; learn two-speed fixed-length operation mode analysis, variable-speed operation mode analysis, table positioning operation mode analysis.

For the advanced knowledge part of positioning control, then you have to learn linkage and linkage and trajectory control analysis, independent single-axis linkage, 2-axis synchronization linkage; learn straight line and arc interpolation, plane curve processing, nonlinear curve processing , Trajectory control analysis (linear trajectory control, circular trajectory control); learn the analysis and application of linear interpolation and circular interpolation, including the concept and classification of interpolation, analysis and application of linear interpolation and circular interpolation, linear interpolation The application of compensation commands and the application of arc interpolation commands.