In the Industry 4.0 era, Pepperl+Fuchs summarizes the changes in sensor technology

In the Industry 4.0 era, Pepperl+Fuchs summarizes the changes in sensor technology

In the Industry 4.0 era, Pepperl+Fuchs summarizes the changes in sensor technology

What changes will the "Industry 4.0" era bring to us? How much can it be used in industry in daily life? Pepperl+Fuchs will summarize the changes in sensor technology?

When evaluating the process data of Pepperl+Fuchs sensors, the real-time nature of data processing must be considered in the application of closed control loops. In this case, because of strict real-time requirements, PLC hardware must be perfectly combined with data communication.

For sensor additional data information, the real-time data processing requirements are not high. But these additional data information must be able to be recorded, stored and processed for a long time.

In addition to signal transmission paths, parallel data paths must be constructed to reach the data platform. For this, we use an edge gateway. The edge gateway can not only establish communication with sensors, actuators, and PLC through the control module, but also establish a connection with the data platform. This is achieved by using a communication protocol that supports the publish/subscribe mechanism, such as MQTT, AMQP, or OPC/UA with Pub/Sub extension.

The data platform can run on the local network inside the factory, or it can be used as an online cloud platform solution. These platforms all have structured databases for storing sensor data; and provide various application interfaces for data access.

Through the application programming interface (API), sensor data can be accessed and transmitted to the platform, which is unique to each system. In order for the edge gateway to connect to this platform, it must also use the API of this platform. Pepperl+Fuchs Group has created a subsidiary, Neoception, to provide high-quality services for this type of software, allowing customers to have the greatest flexibility in choosing a data platform. Neoception combines the expertise of sensors and IT technology and provides interconnection services for all cloud systems available on the market.

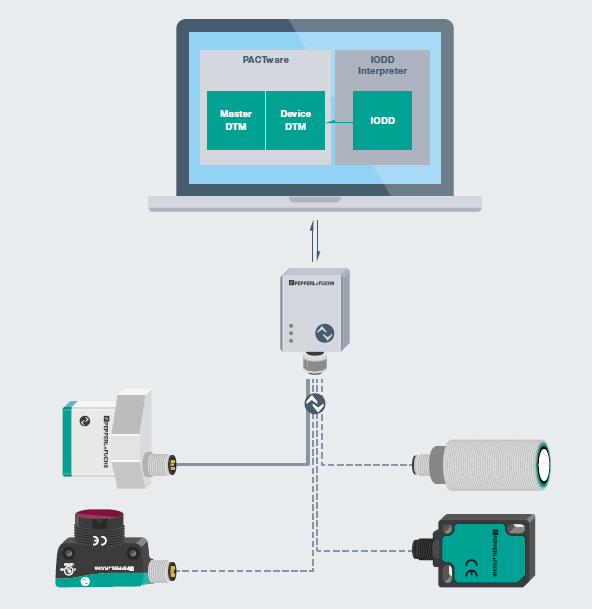

At the sensor/actuator level, there are a series of different communication protocols, but there is no unified semantic set. For each type of field device, appropriate commands must be generated according to specific rules and interpreted according to these rules. The specific attributes of the field device can be found in the description file ("device description", DD for short) provided by the manufacturer with the device. According to different technologies, various description files of different formats (EDDL, GSD, GSDML, IODD, etc.) are used.

The challenge of connecting field devices is to load and interpret device descriptions, and use a common set of semantics so that the data provided by field devices can be accessed in the data platform. Ideally, data access from field devices can be achieved even without knowing the communication technology used.