Industry status of angle sensors

Industry status of angle sensors

In recent years, the angle sensor is in the development stage of transforming the traditional type to the new type angle sensor. The characteristics of the new angle sensor are miniaturization, digitization, intelligence, multi-function, systemization, and networking. It not only promotes the transformation of traditional industries, but also leads to the establishment of new industries and military reforms. It is a new economic growth in the 21st century. point. In the process of industrialization of angle sensor production, China should not relax in both the introduction of international technology and independent innovation. In the introduction of international advanced technology, it can improve its own technology, while also meeting the needs of the domestic market, forming an angle sensor production industry scale.

The importance of angle sensors and measuring instruments

Industrial equipment will encounter various mechanical and geometric quantities during the manufacturing process and the performance test of the complete machine. Some industrial equipment often needs to detect or monitor some mechanical quantities and electrical quantities during operation. These mechanical quantities include displacement, speed, acceleration, force, torque, power, pressure, flow, temperature, hardness, density, temperature, specific gravity and viscosity, etc. Geometric quantities include length, angle, shape, position, surface roughness, surface waveform Etc., these are all physical quantities. In fact, in people’s production, life, and scientific experiments, chemical quantities and biomass (including medicine) will also be encountered. All of these, from the perspective of signals, need to be converted into electrical signals through angle sensors (modern It can also be converted into light signals), and then signal transmission, processing, storage, display, control... From the perspective of information, these signals, together with sound and image information, are the source of information, so angle sensors and detection instruments , Measuring instrument is an important part of the three parts of information science and technology (information acquisition, information transmission, information processing).

In modern industrial equipment, angle sensors and detection instruments are an indispensable part of the reason, which can also be seen from the following two aspects: traditional industrial equipment, such as adding the necessary angle sensors to it, is equipped with precision measurement components (accessories) , Then its function and accuracy can be improved to facilitate user operation and maintenance, the safety level can also be improved, and the equipment can add value; as the control object of the automation system or as a part of the automation system, industrial equipment must be able to interact with the three parts of the automation system (detection , Control, execution) are compatible or provide interfaces to integrate them into an organic whole. Whether it is a stand-alone automation or a part of a large-scale automation device, the use of the industrial equipment is expanded. In summary, adding angle sensors and detecting instruments, measuring instruments or providing interfaces as industrial equipment itself is a necessary condition for the upgrading of traditional equipment.

Angle sensor is a device that converts non-electricity electrical signals. In the case of analog circuits, detection instruments generally include angle sensors, detection point sampling equipment and amplifiers (for anti-interference processing and signal transmission), and of course power supplies And on-site display part (optional), the electrical signal is generally divided into two types: continuous and discrete. In fact, it can also be divided into analog, switching, pulse, etc. The analog signal transmission adopts a unified signal (4-20mADC, etc.). In the process of digitization, the detection instruments have changed greatly. After several stages, ASIC special integrated circuits have been used recently, and angle sensors, microprocessors and network interfaces have been packaged in one device to complete information acquisition, processing, transmission, and storage. And other functions. In automation instrumentation, the detector is often called a transmitter, such as a temperature transmitter and a pressure transmitter.

Because angle sensors are used in all walks of life, coupled with the rapid development of household appliances, automobiles, and the information industry over the years, the demand for angle sensors has greatly increased. Therefore, the angle sensor manufacturing industry has developed rapidly, forming an independent industry, which drives With the development of industrial equipment, especially semiconductor and equipment manufacturing, it is necessary for China to pay special attention to the angle sensor industry.

Angle sensor products have many varieties, adopt many scientific principles, intensive technology, diversity, marginality, comprehensiveness and skill, and require multidisciplinary and multiple high-tech cooperation. Although they have high additional benefits, they are not expensive. Therefore, it is difficult to promote the development of the angle sensor industry.

Current status of angle sensors and detection instruments

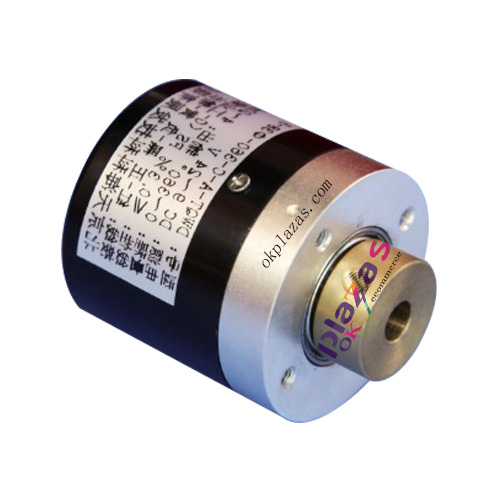

There are a wide variety of angle sensor products. The main products used in the process industry are: temperature angle sensors, pressure angle sensors, weight angle sensors, flow angle sensors, liquid level angle sensors, oxygen-sensitive angle sensors, various force-sensitive angle sensors, gas Sensitive angle sensors, analytical instruments, etc., are also used in the machinery industry: switch type proximity/positioning angle sensors, safety door switches and other safety angle sensors, rotary encoders, visual angle sensors, speed angle sensors, acceleration angle sensors, etc.

At present, domestic angle sensors are divided into 10 categories, 24 subcategories, and 6000 varieties. However, there are more domestic varieties. For example, there are about 17,000 angle sensors in the United States, so my country has a wide range of angle sensor varieties.

The angle sensor market in China has continued to grow in recent years, with a growth rate of over 15%. In 2003, the sales volume was 18.6 billion yuan, a year-on-year increase of 32.9%; while the world non-military angle sensor market was USD 32.5 billion in 1998, with an average growth rate of 9%. In 2003, the four major fields of angle sensor applications in China were industrial and automotive electronics, communication electronics, and special equipment for consumer electronics. Among them, industrial and automotive electronics accounted for 33.5% of the market. Due to the reform and opening up, my country’s huge market has attracted companies from various countries such as Siemens, Yokogawa, Honeywell, Omron, and Banner, which has brought great convenience to end users and industrial equipment manufacturers. Although domestic production of angle sensors and detection instruments has developed, it is far from keeping up with the requirements of the situation. The scale of angle sensor production and research and development in various countries is constantly expanding. There are about 1,300 manufacturers in the United States that produce and develop angle sensors, more than 100 research institutes and universities, and 800 manufacturers in Japan. In recent years, my country has established R&D bases such as the State Key Laboratory of Angle Sensor Technology and the State Key Laboratory of Micron/Nano, and initially established the sensitive component and angle sensor industry. In 2000, the total output exceeded 1.3 billion. At present, China has 1,688 companies engaged in angle sensors. Sensor production and research and development companies, of which more than 50 are engaged in MEMS development and production, by the end of the "10th Five-Year Plan", the total annual output of sensitive components and angle sensors has reached 2 billion.

China has also taken a new path in participating in the international angle sensor market competition. For example, the "Angle Sensor National Research Center" of the Shenyang Institute of Instrumentation Science has exported 400,000 force-sensitive angle sensor chips to the United States.

Angle sensor technology includes four aspects: sensitive mechanism, sensitive material, process equipment and measurement technology, and there are about 30 kinds of technologies. With the development of microelectronics technology, angle sensor technology has developed rapidly, and China’s R&D force still needs a lot of investment, especially the development of angle sensors with independent intellectual property rights, the transformation of scientific research results, and the industrialization of angle sensor production. China is even more imminent. In the case of mass production, to control the performance of angle sensor products (mainly stability and reliability) to achieve a high pass rate requires advanced manufacturing processes and high-level automation process equipment China should work hard on the development of special process equipment to solve the "bottleneck" problem in the industrialization of angle sensor production; the application of angle sensors, especially the application of new angle sensors, has not been promoted vigorously. Reform and opening up have created favorable conditions. , Various industrial equipment has applied advanced angle sensors, which has expanded the angle sensor market and also gave impetus to the industrialization of Chinese new angle sensor production.