Italy Eltra Magnetostrictive Sensor

Italy Eltra Magnetostrictive Sensor

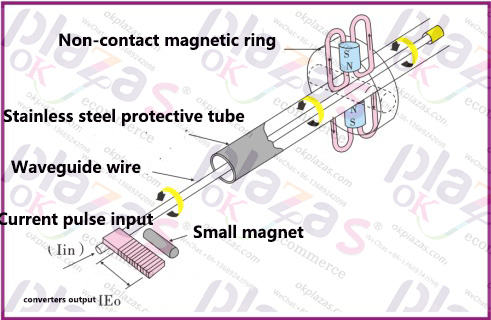

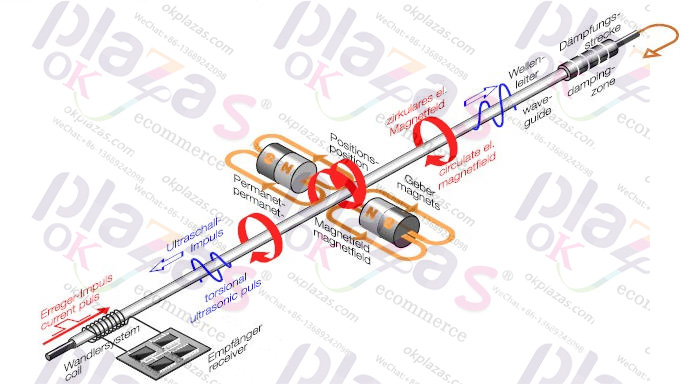

The working principle of the magnetostrictive sensor: When measuring, the pulse generator generates a waveguide pulse, which is processed by the electronic part and transformed into a current pulse that propagates along the waveguide line, that is, the initial pulse. The magnetic field generated by it is superimposed with the magnetic field formed by the magnetic ring. Generate instantaneous torsion, twist the waveguide wire and generate a tension pulse. This pulse is transmitted back along the waveguide wire at a fixed speed. The induced current pulse is generated at both ends of the coil to terminate the pulse. By measuring the time difference between the start pulse and the end pulse You can accurately measure the liquid level or displacement.

The change of the magnetization direction in the ferromagnetic material will cause the change of the lattice spacing of the medium, thus causing the length and volume of the ferromagnetic material to change, namely: the magnetostriction phenomenon, also known as the Widman effect, and its inverse effect is the dimension Larry effect. But not all ferromagnetic materials have application value, and only some new materials with high magnetostrictive properties have practical application value.

Features of magnetostrictive sensor:

1. Easy to install

2. Long service life

3. Isolation and explosion-proof

4. No need for regular re-standard and maintenance

5. Lightning protection, radio frequency interference

6. Multiple signal output mode selection

7. With reverse polarity protection

8. Exquisite structure, strong environmental adaptability

9. High precision, high stability, high reliability

10. Can monitor the liquid level of the pressurized or non-pressurized liquid tank

Magnetostrictive liquid level sensor application:

1. Oil tank level measurement

2. Dam water level monitoring

3. Liquid level control of pharmaceutical tank

4. Chemical process level control

5. Food and beverage liquid tank control

6. Drinking water and sewage treatment

Magnetostrictive sensor performance index:

1. Resolution: better than 0.01% FS

2. Late lag: better than 0.01%FS

3. Zero adjustment range: 20%FS

4. Full scale adjustment range: 20%FS

5. Frequency response time: 0.2~5ms

6. Repeatability error: better than 0.01% FS

7. Temperature influence: ±0.007%FS/℃

8. Non-linear error (±%FS): 0.05; the maximum error is 150μm below the range of 300mm.

The magnetostrictive sensor is a high-precision, ultra-long stroke absolute position measurement sensor manufactured by the principle of magnetostriction. This product is composed of pulse circuit, waveguide line, echo signal unit, structural parts and protective sleeve. It has the characteristics of high precision, reliable stability, long life, easy installation, and multiple output modes to choose from. It can not only measure The linear displacement of the moving object, and the analog signal of the displacement and speed of the moving object can be given. Due to the non-contact measurement method, the sensor has stable performance, long service life, and multiple output modes for selection. Therefore, it is widely used in petrochemical, food, water treatment, environmental protection, pesticide, papermaking, reservoir, dye, hydraulic machinery and other industrial equipment. 2. Working principle When measuring, the pulse generator generates a waveguide pulse, which is processed by the electronic part and transformed into a current pulse that propagates along the waveguide line, that is, the initial pulse. The magnetic field generated by the pulse generator and the magnetic field formed by the magnetic ring are superimposed to produce instantaneous torque , The waveguide wire is twisted and a tension pulse is generated. This pulse is transmitted back along the waveguide wire at a fixed speed, and the induced current pulse is generated at both ends of the coil, that is, the termination pulse. The time difference between the initial pulse and the termination pulse can be measured Accurately measure liquid level or displacement.

The magnetostrictive sensor uses the time when the strain pulse signal generated when two different magnetic fields are intersected is detected to calculate the accurate position of the magnetic field intersection. A magnetic field is excited by a pulse generated by the electronic component of the sensor’s electronic compartment. The magnetic field generated by the excitation pulse moves from the end of the electronic compartment to the end at the speed of light along the waveguide filament made of high magnetostrictive material in the sensor rod. When it intersects with the active permanent magnetic field (the permanent magnet is generally installed on the moving plate where the detection position is needed), due to the magnetostriction phenomenon, the waveguide wire generates a mechanical strain pulse at the intersection point, and from this point through the waveguide wire to the electron at the speed of sound The warehouse end returns, and the strain pulse is detected by the detection circuit in the electronic warehouse.