okplazas.com shares A new solution for circuit board production and inspection-Pepperl+Fuchs PMI sensor series!

okplazas.com shares A new solution for circuit board production and inspection-Pepperl+Fuchs PMI sensor series!

okplazas.com shares A new solution for circuit board production and inspection-Pepperl+Fuchs PMI sensor series!

One of the processes in the production of printed circuit boards is to classify the stacked circuit boards into different types by vacuum chucks. The function of the vacuum chuck is to detect whether the layered circuit board is adsorbed, or only the separated layer is adsorbed. In the past, this detection operation was done by expensive color sensors, and each time a new color was encountered, a pre-calibration program was required to reprogram the color sensor. As an international company specializing in automation services for many years-okplazas.com, today I will share with you the latest solutions for the inspection of the circuit board production process. The focus of this new solution is the newly launched PMI inductive analog sensor from Pepperl+Fuchs.

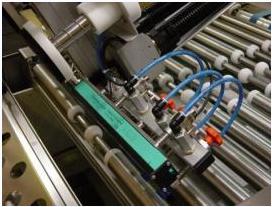

Pepperl+Fuchs PMI sensor products detect printed circuit boards

The PMI inductive analog sensor introduced by the German P+F company provides a brand-new solution for this work. The P+F sensor PMI series adopts the inductive working principle to detect, eliminating the need for a new pre-calibration process when changing materials. The PMI sensor is elastically suspended on the circuit board and the separation layer to gently generate suction. Because it uses analog output, it can achieve precise control system measurement. In addition, the PMI sensor has a wide detection range and sufficient sensitivity for detecting copper.