On-site emergency use of SEW inverter DGB60B handle

On-site emergency use of SEW inverter DGB60B handle

SEW's inverter debugging tool Motion Studio has powerful debugging functions, which can scan the inverter in the network, upload and download parameters, manually control the operation of the inverter, use the expansion module DEH11B to collect the encoder signal for positioning and so on. But sometimes, there is not much time for the on-site inverter alarm to take the computer for online debugging. We need to quickly modify a parameter or reset the fault to ensure the operation of the production line. In this case, the key board of the inverter can play a very important role. I once encountered a sudden inverter alarm at the scene and used the operating handle to eliminate the fault. Well, today in this article, let us talk about how to use the DBG60B operating handle (Key Board) of the SEW MDX60/61B inverter.

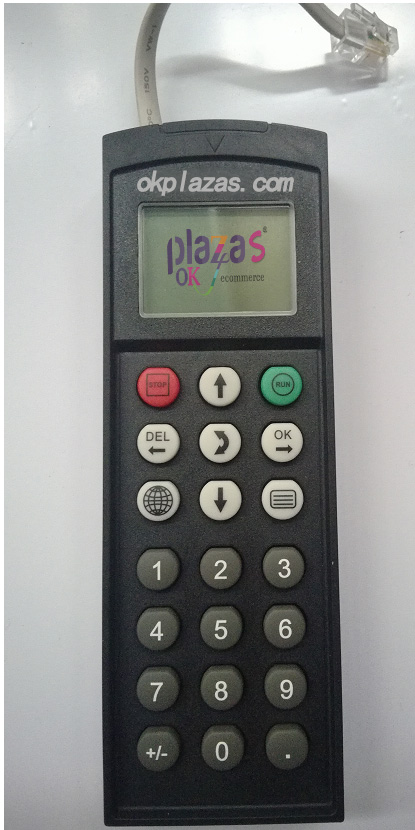

The following picture shows the appearance of the SEW MDX61B inverter. The black component with a display screen and many buttons on the front is the DBG60B operating handle (Key Board):

The DBG60B operating handle (Key Board) is connected to the main body of the inverter through a RS485 communication line and can be removed, as shown below:

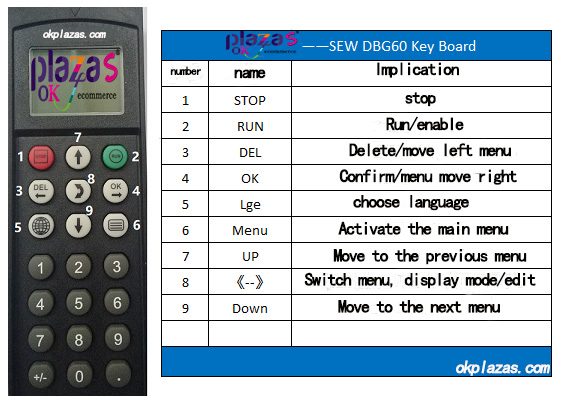

At the top of the handle is an LED display. Below the display, there are seven rows of buttons. The first three rows are control buttons. The meanings are as follows:

The language menu can be activated through the language key, press the up and down movement keys to select the desired language, and press the OK key to confirm. As shown below:

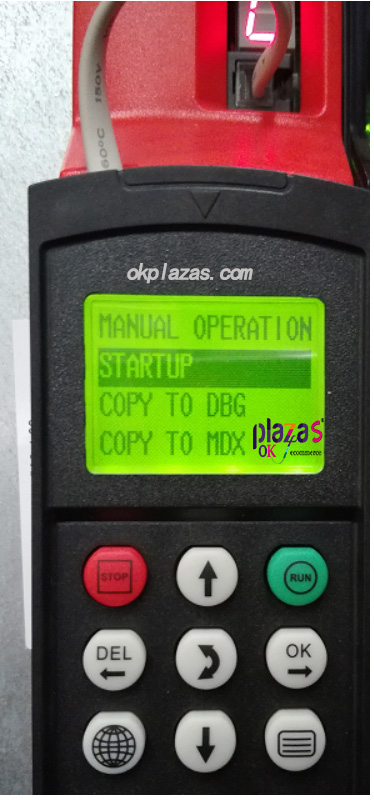

The DBG60B operating handle (Key Board) can perform simple debugging. Press the main menu button and move up and down to "StartUP" to set the motor parameters (voltage, current, power, etc.).

The DBG60B operating handle (Key Board) can also copy the parameters of the inverter between the handle (Key Board) and the inverter. This is very convenient when debugging multiple inverters with similar functions.

Below we introduce the specific steps of using the DGB60B operating handle to realize parameter copy:

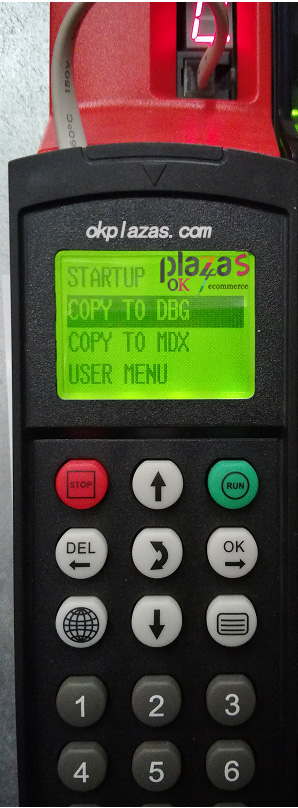

Activate the main menu, press the up and down movement keys to find the menu "COPY TO DBG", press OK to confirm, as shown in the figure below:

In this way, the parameters of the inverter are copied to the operating handle.

Remove the handle, connect it to another inverter, activate the main menu, select "COPY TO

MDX" and confirm, you can copy the parameters in the handle to the new inverter.

When a fault alarm occurs during the operation of the inverter, the inverter will stop running and display the fault code in sequence on the 7-segment digital tube. The cause of the fault can be found according to the fault code. If you want to confirm the fault, you can press the [DEL] key.

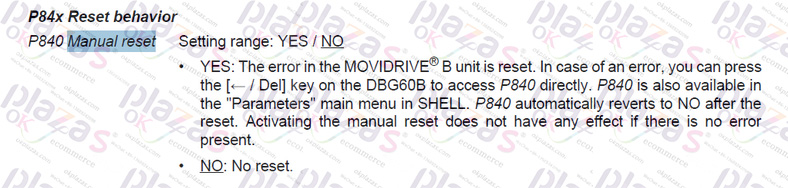

The [DEL] key of DBG60B will activate parameter P840 (Manual Reset), which tells the inverter that the parameter fault has been reset. Regarding P840 parameters, you can refer to the following paragraph:

Ok, let’s talk about the DBG60 operating handle of SEW inverter first.