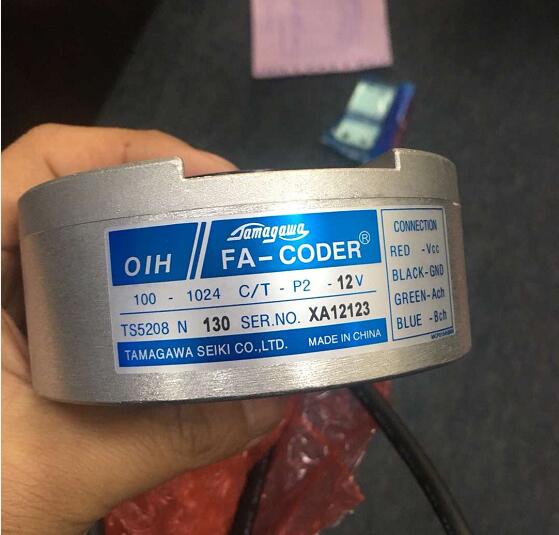

Rolling machine encoder

Rolling machine encoder

The encoder of the plate rolling machine consists of a photoelectric code disk with a shaft in the center, on which there are ring-shaped and dark engraved lines, and read by photoelectric transmitting and receiving devices to obtain four groups of sine wave signals combined into A, B, C, D , Each sine wave has a phase difference of 90 degrees (relative to a cycle of 360 degrees), the C and D signals are reversed and superimposed on the A and B phases to enhance the stable signal; in addition, a Z-phase pulse is output per revolution To represent the zero reference position. Since the phases A and B are different by 90 degrees, the encoder's forward and reverse rotation can be judged by comparing whether the A phase is the first or the B phase. The zero reference position of the encoder can be obtained through the zero pulse.

The materials of the encoder code disc of the coiling machine are glass, metal, plastic. The glass code disc is a thin engraved line deposited on the glass, which has good thermal stability and high accuracy. The metal code disc is directly engraved with and without pass. Not fragile, but because metal has a certain thickness, the accuracy is limited, and its thermal stability is an order of magnitude worse than that of glass. The plastic code wheel is economical, and its cost is low, but the accuracy, thermal stability, and life are all It's worse.

Resolution-The number of open or dark engraved lines provided by the encoder of the plate rolling machine per 360 degrees of rotation is called the resolution, also known as the resolution index, or the number of lines directly, generally 5 to 10,000 lines per revolution.

okplazas.com specializes in the production and sales of various coiling machine encoders, and can provide coiling machine encoder selection, coiling machine encoder quotation, coiling machine encoder installation instructions, coiling machine encoder maintenance and other services, welcome to consult !