Siemens soft starter 3RW51 model parameters and troubleshooting methods

Siemens soft starter 3RW51 model parameters and troubleshooting methods

Siemens soft starter 3RW51 model parameters and troubleshooting methods

Overview of Siemens soft starter 3RW51

It can be said that this equipment is developed and manufactured on the basis of Siemens' deep experience in soft start applications. The 3RW51 soft starter can be used for loads that need to control the start and stop of fans, conveyor belts, compressors and pumps. Installation and use on occasions.

Basic features of Siemens soft starter 3RW51

◆Using three-phase control.

◆Rated working voltage: 200 to 480VAC, -15% to 10%.

◆Rated control power supply voltage: 110 to 250V, 50Hz/60Hz, -15% to 10%.

◆External bypass contactor.

◆Siemens soft starter can also choose to use standard wiring or inner delta wiring.

◆The equipment is equipped with a protective coating control panel, which can effectively resist dust, humidity and corrosive gases.

◆The standard operation or high-performance operation panel can also be selected.

◆The soft starter can support a variety of mainstream communication protocols.

◆With analog output, 4-20mA, 0-10V signal optional.

◆With soft torque and pump stop function.

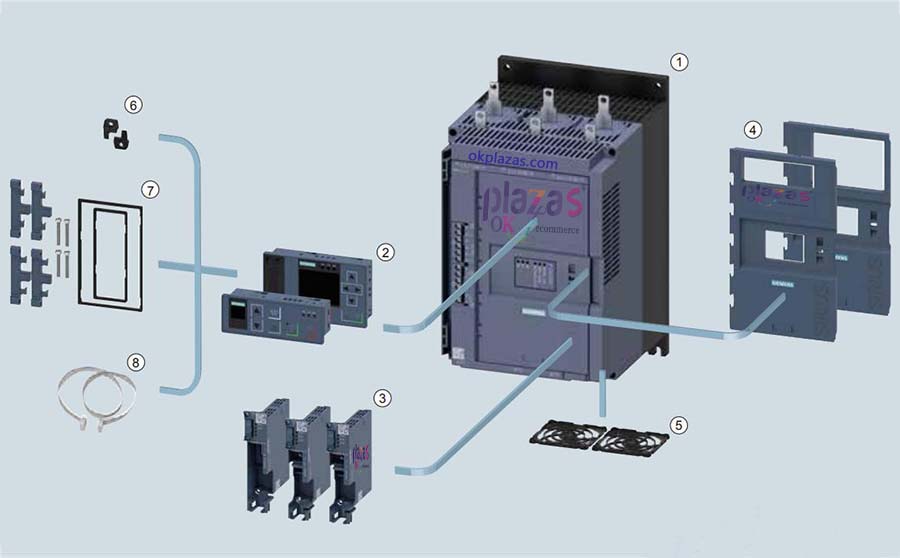

Siemens soft starter 3RW51 external structure

The external structure of the equipment is shown in the figure below

1. Soft starter 3RW51 body; 2. Operation panel; 3. Communication module;

4. Front cover with operation panel opening; 5. Fan cover;

5. Operation panel cabinet door installation accessories; 7. Operation panel IP65 cabinet door installation accessories;

8. Cable (between the operation panel and the soft starter).

The working principle of Siemens soft starter 3RW51

Its main function is to limit the starting current and starting torque, and it can also reliably prevent the occurrence of mechanical shocks and grid voltage drops during the starting process. The working principle of the Siemens soft starter 3RW51 model is to use the control of the thyristor conduction angle to reduce the voltage when the motor starts, and to increase the motor starting voltage to the rated voltage within the specified starting time range.

Siemens soft starters rely on this kind of motor voltage without any step-like control, and can effectively adjust the motor according to the load characteristics of the driven machine, so that it can smoothly accelerate the equipment and indirect mechanical equipment. Operational capability has been improved to a certain extent, while also reducing daily maintenance costs and increasing and extending service life.

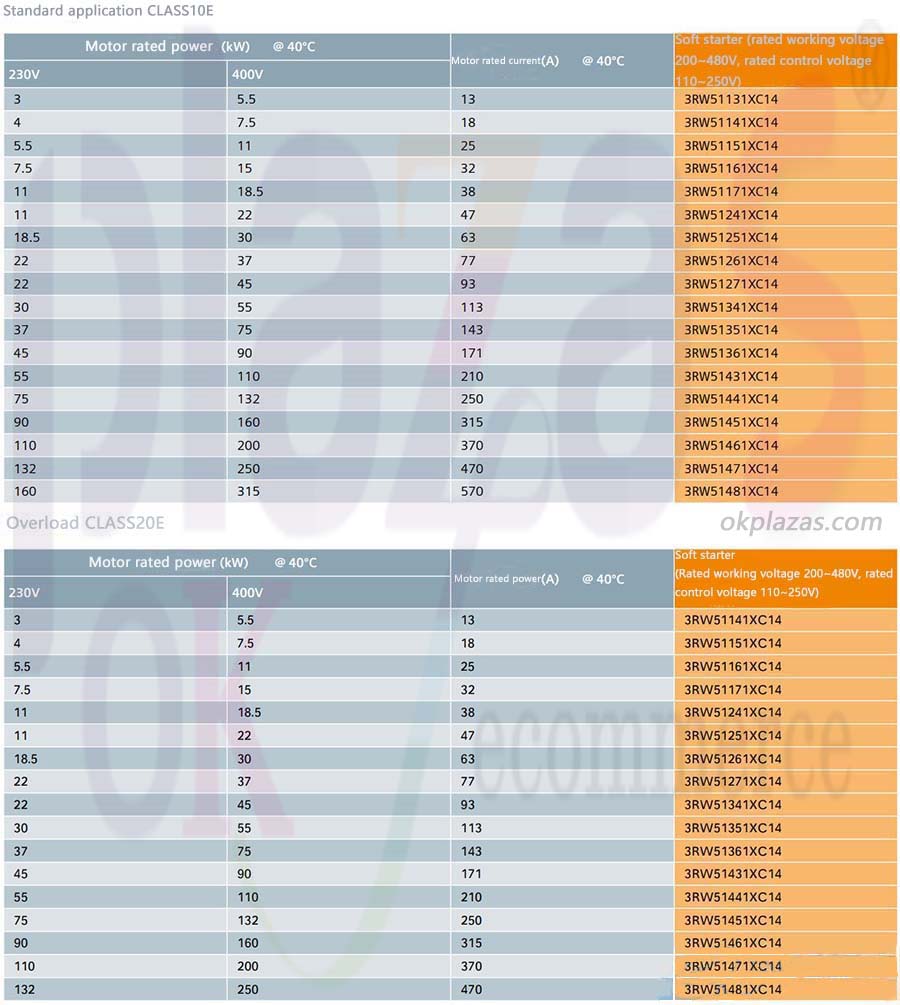

Siemens soft starter 3RW51 technical parameters

The technical parameters (standard wiring) of the soft starter 3RW51 are shown in the figure below

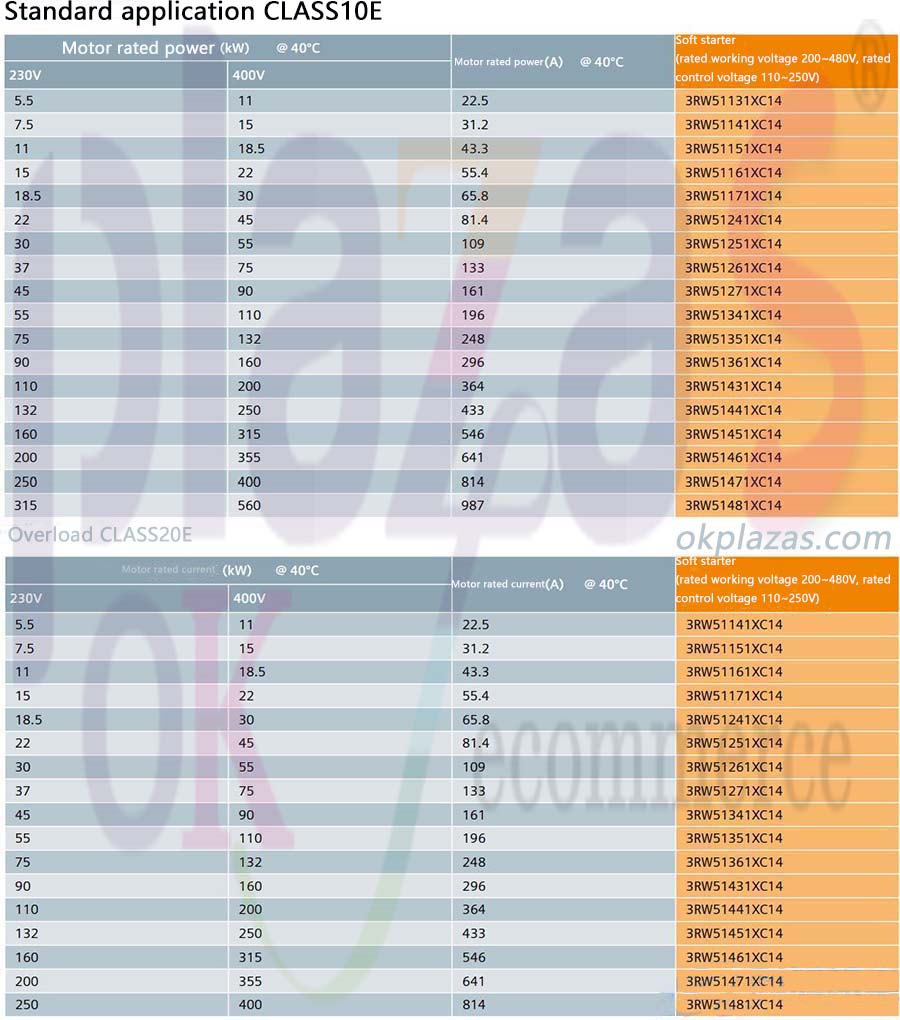

The technical parameters of the soft starter 3RW51 model (inner delta wiring) are shown in the figure below

iemens soft starter 3RW51 application range

The equipment is widely used in metallurgy, petrochemical, construction, mining, papermaking, automobile and textile industries. Commonly used loads are as follows:

◆Water pump-soft starter can improve the water hammer effect, and also provide better protection for pipes, seals, valves and other mechanical parts.

◆The fan-soft starter can reduce mechanical wear and at the same time reduce the impact on the power grid, saving maintenance costs to a certain extent.

◆Compressor-equipment can achieve smooth starting and extend the service life of the motor.

◆Belt conveyor-reduce the damage to the belt caused by mechanical impact, avoid the displacement of the transported materials, and protect the transported objects.

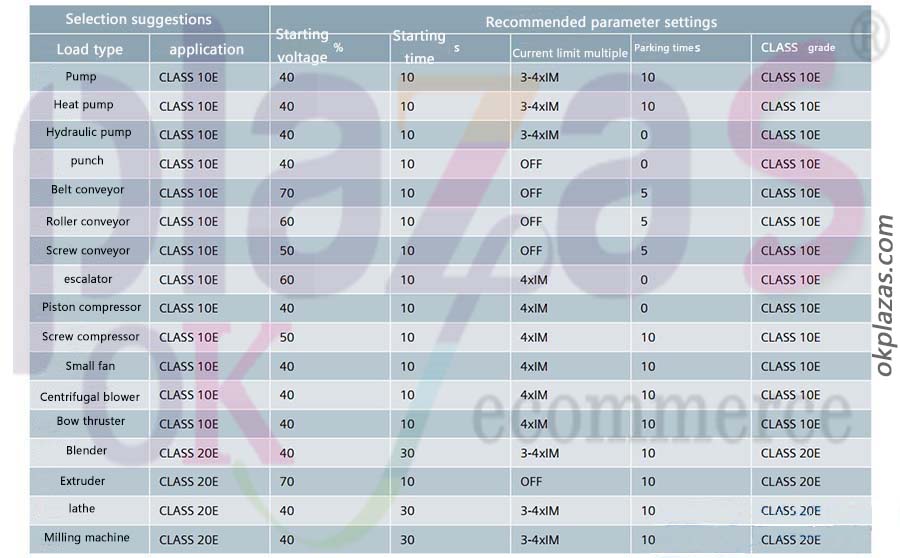

Recommendations for Model Selection of Siemens Soft Starter 3RW51

The soft starter selection and parameter setting suggestion are shown in the figure below

Note:

1. It is best to fully understand the characteristics and usage of the load;

2. When the Siemens soft starter is in use, the specification should always be greater than the current value of the current (that is, the rated working current). If there is a deviation from the rated value, it is recommended to use a soft starter with a larger specification.

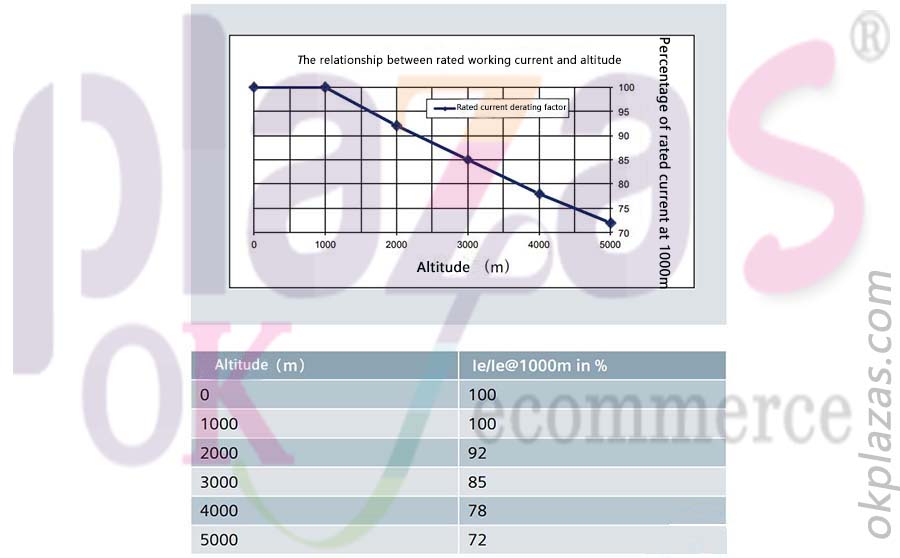

3.The reasonable installation altitude is 5000 meters and below. When it is above 1000 meters, derating is needed. The curve of rated working current and altitude is shown in the figure below.

Siemens soft starter 3RW51 use requirements

◆Conform to standard: EN/IEC60947-4-2;

◆Equipment certification: CCC national standard;

◆Protection level: IP00;

◆Environmental temperature: -25℃ to +60℃ during operation (derating at +40℃), -40℃ to +80℃ during storage;

◆The highest environmental pollution level: III;

◆Ventilation requirements for the installation of the soft starter: 100mm on the upper part, 5mm on the side and 75mm on the lower part;

◆Maximum length of connectable cable: 800 meters.

Electrical characteristics of Siemens soft starter 3RW51

◆Operation category: AC53a;

◆Rated current of soft starter: 13 to 987A;

◆Motor power: 5.5 to 315kW;

◆Frequency: 50Hz/60Hz, -10% to +10%;

◆The highest energy consumption of the control circuit: 70mA in bypass operation, 96mA with fan and 76mA without fan during starting (if the Siemens soft starter with rated current less than 77A does not have a fan);

◆Optional communication protocol: PROFIBUS, PROFINET, MODBUS-RTU;

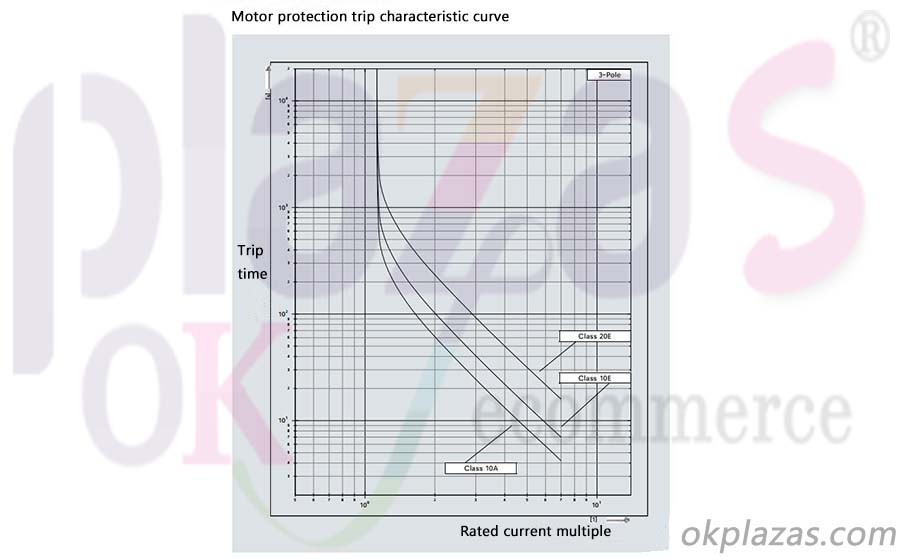

◆The characteristic curve is shown in the figure below.

Siemens soft starter 3RW51 accessory configuration

◆Communication module: PROFIBUS template, PROFINET template, MODBUS-RTU template;

◆Operation panel: high performance operation panel, standard performance operation panel;

◆High-performance operation panel: operation panel cabinet door installation accessories, (high-performance and standard) front panel with holes;

◆Fan cover, control line slot cover, memory card, etc.

Siemens soft starter 3RW51 wiring method

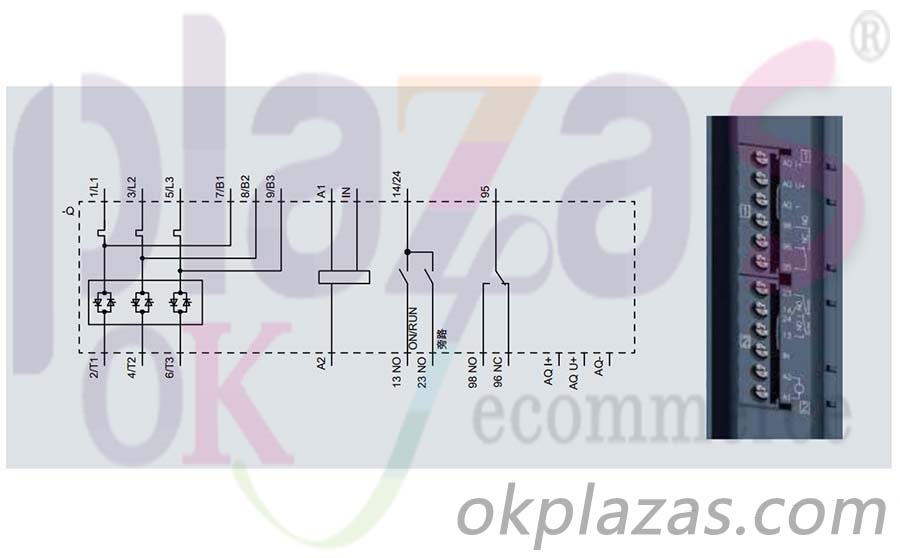

The internal wiring diagram of the soft starter is shown below

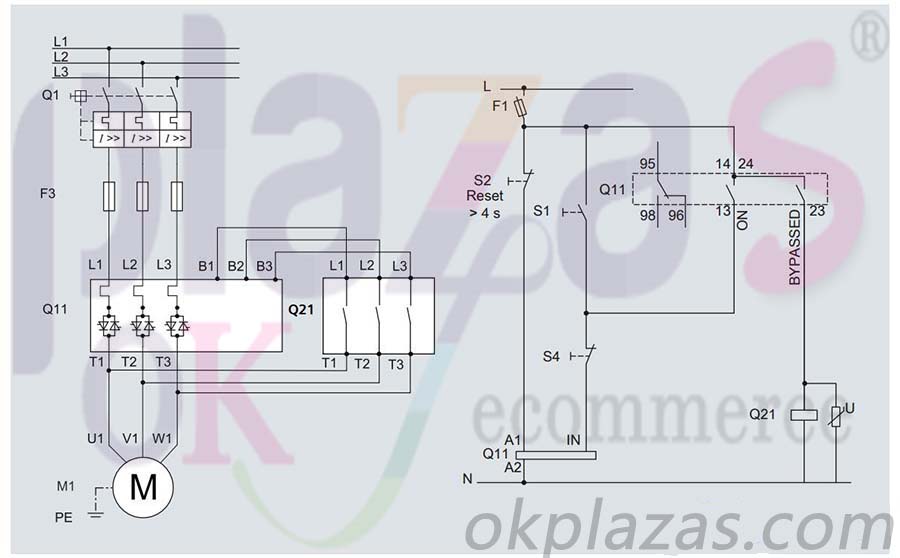

Wiring diagram of single motor soft starter controlled by button

Siemens soft starter 3RW51 failure and its solution

Failure code: 303

Fault description: bus fault

Solution: Confirm by automatic reset

Fault code: 308

Fault description: The contact block fails

Solution: ●Check the switching elements L1, L2 and L3, ●Replace the faulty equipment

Fault code: 309

Fault description: contact block overload

Cause of failure: overheating of contact block (switch contact, power semiconductor)

Solution: ●Check the cooling environment conditions, may need to consider derating, ●check the number of switch operations, ●confirm after cooling

Fault code: 317

Fault description: electronic equipment power supply voltage is too low

Cause of failure: power supply voltage is lower than allowable

Solution: ●Check the power supply (load size, voltage range)

Fault code: 319

Fault description: no power supply voltage

The cause of the failure: ●The power switch is off or the power supply is not connected correctly, ●No current

Solution: Check the cable and cable connection, and replace all faulty components

Fault code: 327

Fault description: motor thermal model overload

Causes of the fault: ●The motor feeder is overloaded, ●The temperature of the motor exceeds the limit

Solution: ●Please check the motor and the application items of the motor drive, ●After the trip, you can restart the motor at the end of cooling or after clearing the thermal memory of the motor

Fault code: 328

Fault description: motor overload trip

The cause of the failure: ●The motor feeder has been overloaded, ●The temperature of the motor exceeds the limit

Solution: ●Please check the motor and the application items of the motor drive, ●After the trip, you can restart the motor at the end of cooling or after clearing the thermal memory of the motor

Fault code: 355

Fault description: Process image error

Cause of failure: Process image output (PIQ) includes invalid control bit combinations (for example, clockwise and counterclockwise rotation control bits set at the same time)

Solution: ●Check and correct the process image output (PIQ), ●Confirm immediately after sending a valid process image

Fault code: 378

Fault description: Invalid/inconsistent firmware installed

Failure reason: firmware is incomplete and or firmware extension is incomplete and incompatible

Solution: ●Perform a complete estimated update, ●Check all possible failure information, ●Check to make sure whether the estimated update has been interrupted

Fault code: 381, 1523

Fault description: soft starter fault

Cause of failure: An unrepairable error is detected after self-diagnosis (self-check, contactor contact, contact block, etc.)

Solution: ●Replace equipment, ●Find dedicated technicians for maintenance

Failure code: 1408

Fault description: no load

The cause of the fault: The current is not detected in the motor feeder after the ON command may be ●Main circuit interruption (fuse and motor starter protector), ●Motor contactor or contactor control failure, ●No load

Solution: ● Confirm immediately after eliminating the cause

Fault code: 1409, 1410, 1411

Fault description: phase loss L1, phase loss L2, phase loss L3

Failure reason: the main energy monitoring system has detected a lack of phase

Solution: ● Confirm immediately after eliminating the cause

Fault code: 1466, 1467, 1468

Fault description: contact 1 failure, contact 2 failure, contact 3 failure

Failure reason: power semiconductor is damaged

Solution: ●Check the contact blocks of L1, L2 and L3, and replace the faulty contact blocks, ●Find professional technicians for repair

Failure code: 1482

Fault description: beyond the current measurement range

The cause of the failure: ●The measured value of the sensor has exceeded the range limit, ●The output value of the actuator has exceeded the upper limit

Solution: ●Check the connection between the module and the sensor or actuator

Siemens soft starter 3RW51 reset mode

Function: Setting the reset mode will only affect the confirmation response of the motor overload protection.

Manual reset of the soft starter means that the error can be confirmed by the following options:

◆ RESET/TEST button on 3RW51 soft starter;

◆The RESET/TEST button on the standard 3RW5 HMI;

◆Reset through the bus interface;

◆Reset via the F key on the high-performance 3RW5 HMI;

◆Reset via high-performance 3RW5 HMI.

The remote reset of the soft starter means to confirm the fault by turning off and then turning on the control power supply voltage. The control power supply voltage on the Siemens soft starter 3RW51 model must be turned off for at least 3 seconds.

The automatic reset of the soft starter means that the fault can be automatically reset immediately after the cause is eliminated.

okplazas.com is an electromechanical professional agent selling Siemens products. Welcome to email: [email protected] for consultation, and you can also contact WeChat customer service +86-13689242098 online for product consultation!