Siemens soft starter 3RW55 start function and principle

Siemens soft starter 3RW55 start function and principle

The start mode of the Siemens soft starter is used to determine the ramp mode of the motor after receiving the start command. The following starting modes can be set:

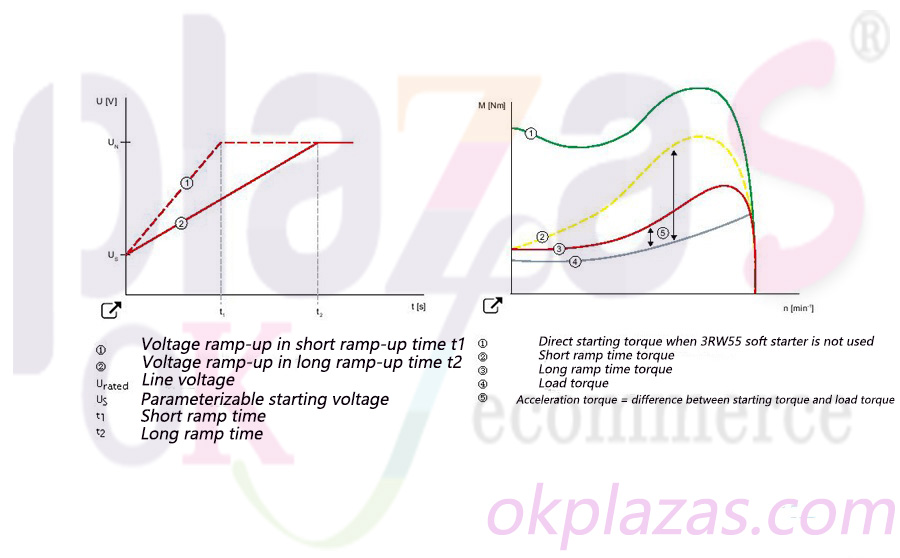

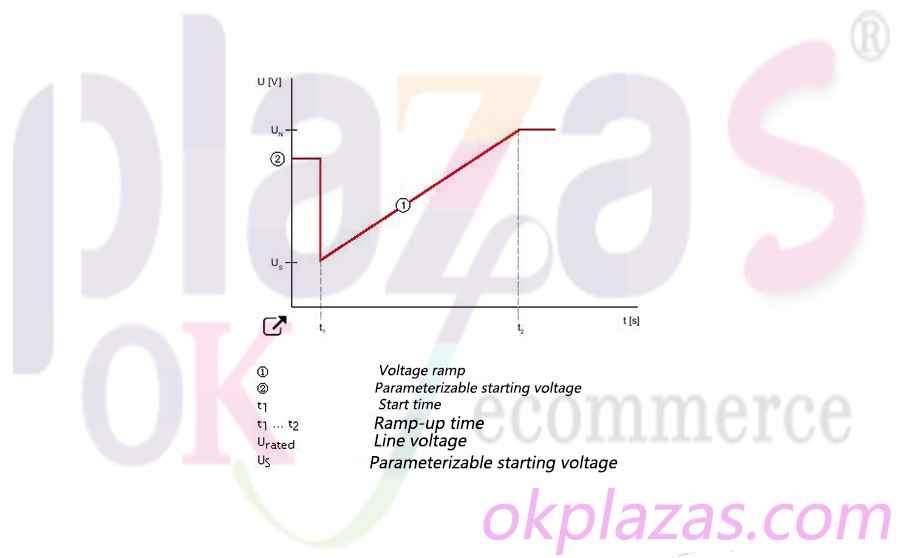

●Soft start based on voltage ramp

Principle: Use a voltage ramp to achieve soft start. Within a definable ramp-up time, the 3RW55 soft starter will increase the motor voltage from the parameterized start voltage to the line voltage, which can be applied to conveyor belts or requires no severe interference when the drive starts In the system.

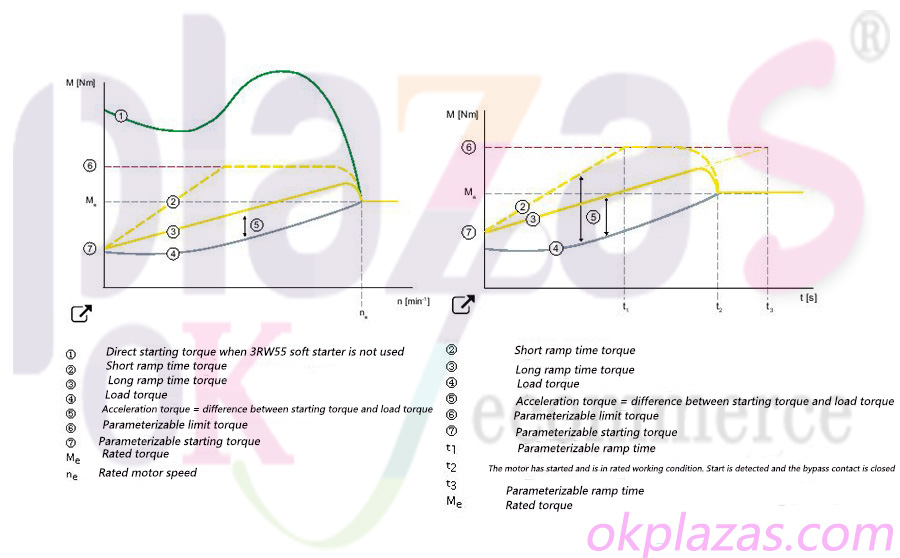

●Soft start based on torque control

Principle: Torque control means that within the adjustable starting time, the torque generated in the motor will be linearly increased from the parameterizable starting torque to the parameterizable ending torque.

This improves the mechanical starting behavior of the machine compared to the voltage ramp. The Siemens soft starter continuously and linearly controls the torque generated in the motor according to the set parameters until the motor is completely started.

In order to ensure that the best torque control is implemented during the starting process, the motor data of the motor connected to the soft starter should be entered in the selected parameter group, which can be applied to uniformly reduced load-type ramps or machines that require starting pulses, such as mills. Machines, crushers and drive units with sliding bearings.

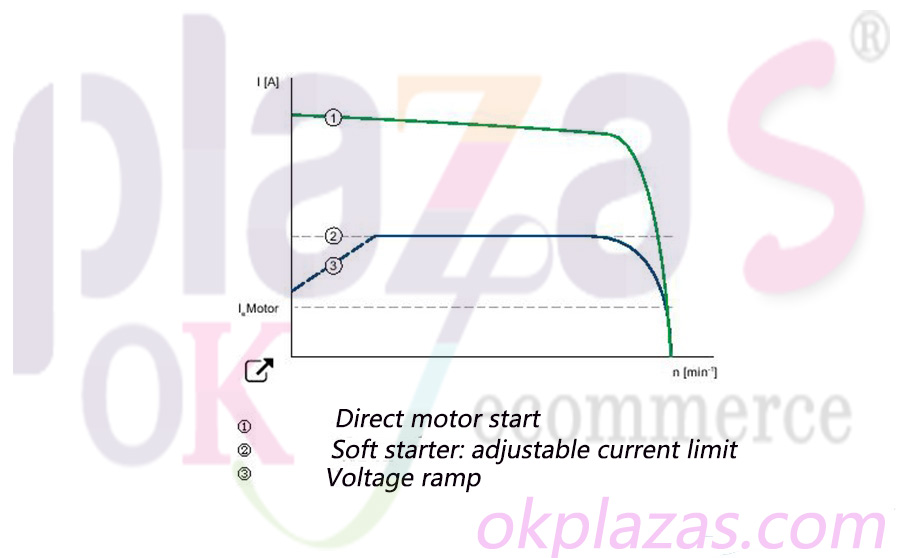

●Soft start based on voltage ramp and current limit

Principle: If you want to protect the system during starting and ensure that the motor does not exceed a specific current value during starting, please select the starting function voltage ramp + current limit.

When the motor starts, the voltage always ramps up. If the current exceeds the parameterized current limit, the voltage ramp function will be aborted and the current limit function will start. If the motor current drops below the limit again, according to the later stage of the start, the voltage ramp function will re-control until the end of the motor start, which can be applied to avoid current surges and reduce energy consumption.

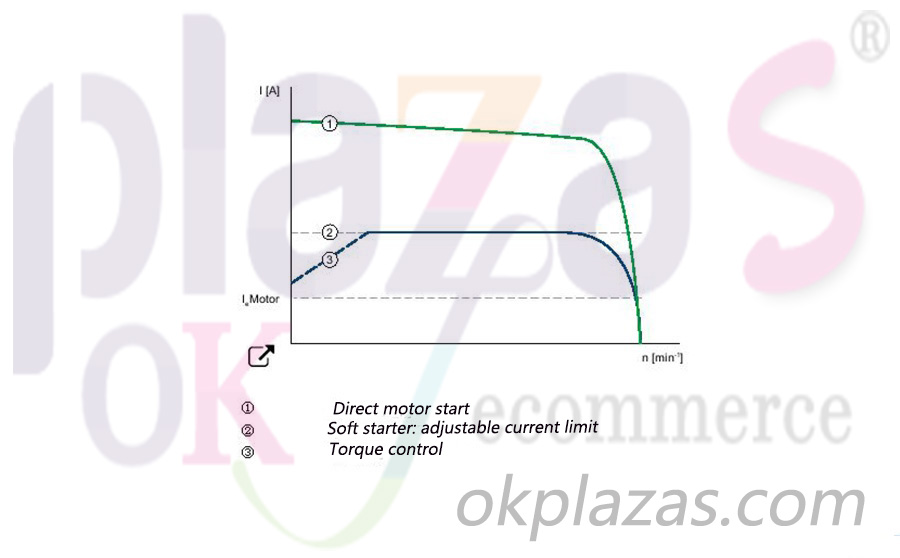

●Soft start based on torque control and current limit

Principle: If you want to protect the system while starting the motor or the connected load while ensuring that a specific current value is not exceeded, please select the starting function torque control + current limit.

When the motor is started, torque control is always used. If the current exceeds the parameterized current limit, the torque ramp will be aborted and the current limit function will start. If the motor current drops below the limit again, according to the later stage of the start, the torque ramp function will re-control until the end of the motor start. It can be used in scenarios such as avoiding current surges, reducing energy consumption, and during heavy starting.

●Direct start

Principle: The motor starts immediately, and there is no closed-loop control in the direction of rotation (right/clockwise = line phase direction). For example, direct starting is not affected by the current limit of the soft starter.

If the "direct" start mode is set, the motor voltage will immediately increase to the power supply voltage level after the start command is issued. This is equivalent to the starting behavior realized by using a contactor, that is, there is no restriction on starting current and starting torque.

●Motor heats up

Principle: The motor can be heated in the "motor heating" starting mode, and the motor will not start. As long as there is a "motor forward" or "motor reverse" control command, the motor heating function will remain open. Specify a set of custom parameters for the motor heating function to make the switch between motor heating and actual starting faster and simpler. It is suitable for drives used outdoors, which can minimize the condensation water inside the motor.

●Start pulse for start function

Principle: It may be necessary to generate a starting pulse at the beginning of the machine starting process. With the help of starting pulse, the upper limit of load friction can be overcome and the machine can be operated. The start pulse is used in combination with the start type of voltage ramp, torque control or current limit, and it will overlap within the set start time. The Siemens soft starter with this starting function is mainly used in mills, crushers, driving devices with sliding bearings and other places.

●Automatic parameterization

Principle: After activating automatic parameterization, the soft starter will optimize the starting parameters each time the motor starts. The recommended parameters of the selected application will automatically be used as the starting value of the automatic parameterization: for the preset starting time, the ramp-up time is used as the starting value, and for the current limit, the application preset value is used.

When selecting the parameters, the motor should be able to start with the minimum current immediately and will not vibrate during the starting process. Automatic parameterization can be set for each parameter group, and then the rated operating current Ie of the motor connected to the Siemens soft starter 3RW55 can be adjusted.

After storing the parameters, you can view the automatically determined values in the parameter settings of the corresponding parameter group. If automatic parameterization is disabled, the stored value will no longer be modified. Only after the device is parameterized again, the parameters learned in the device will be overwritten.

okplazas.com Electromechanical Mall is a professional sales agent for Siemens products, welcome to email: [email protected] for consultation, and you can also contact WeChat customer service online at +86-13689242098 for product consultation!