The working principle and structure of permanent magnet governor

The working principle and structure of permanent magnet governor

Working principle of permanent magnet governor

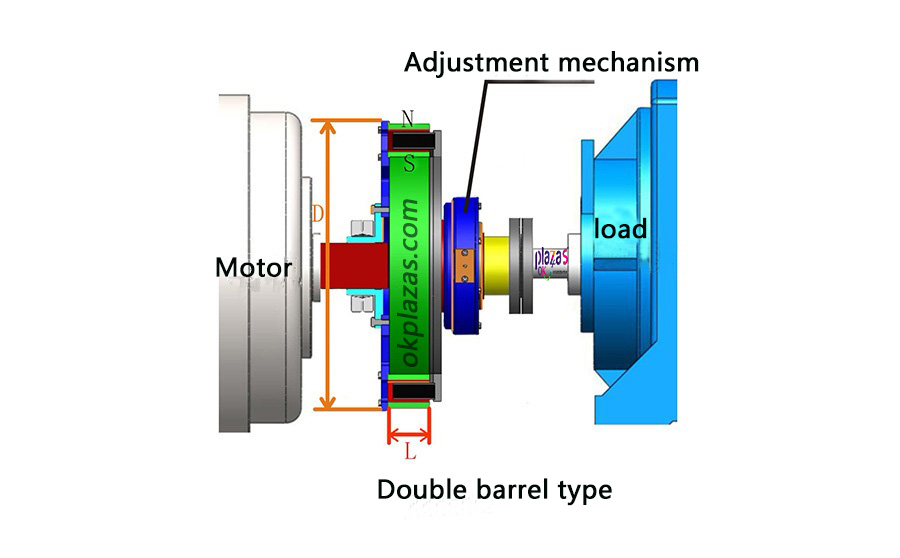

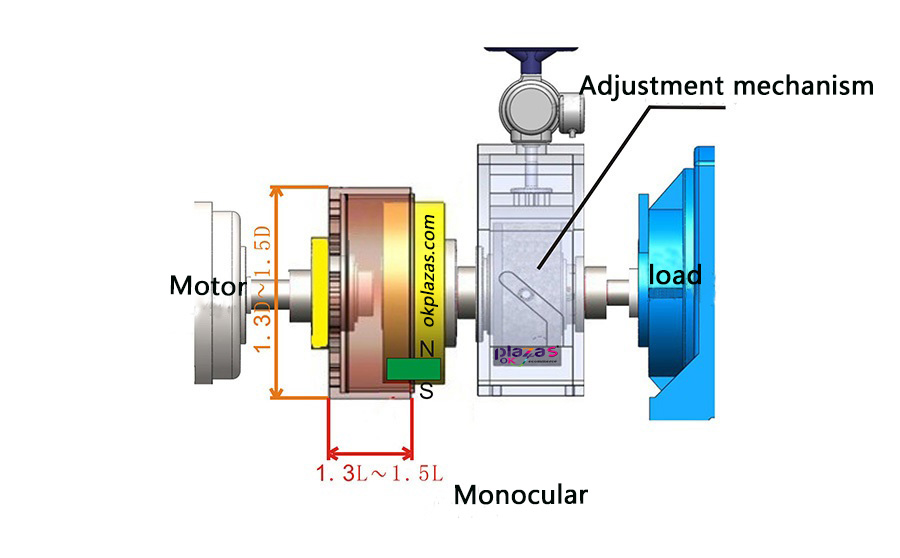

Usually the device is assembled by three main parts, one is the permeable magnet that is connected to the motor, and the other is the permanent magnet that is connected to the load, and there is a certain space between the two rotating parts. gap. The third is the use of a regulator, which can adjust the space gap distance between the permanent magnet governor rotors, and at the same time, the load output speed can be controlled by adjusting the load torque.

Simply speaking, the working principle of the permanent magnet governor is to use torque to control the speed. The torque output from the motor to the governor is the same as the torque output by the device. In this way, we can adjust the output of the motor according to the torque during the actual load operation. If the torque required by the load is small, the torque output by the motor is small and the corresponding output power will also be reduced accordingly.

The input speed and output speed of the permanent magnet governor are the same, and due to the existence of the air gap between the two rotating bodies, if the output speed is lower or smaller than the input speed, this phenomenon can be called "slip" And the size of the slip determines the size of the transmitted torque, so the purpose of speed control is achieved.

Structure composition of permanent magnet governor

We have said before that the permanent magnet governor is mainly assembled from three parts. In addition, its structure is divided into end caps, bearings, grease and other parts. Next, we will talk about the structure of the outer rotor and inner rotor of the permanent magnet governor in detail. The details are as follows.

◆Partial structure of outer rotor

1. First of all, it is suitable for a fixed magnetic field, and it is composed of shell, tile magnet, inter-pole brace and other components;

2. The end cover is usually made of cast iron or cast steel, and its function is to fix the rotor in the inner cavity of the inner rotor, so that the rotor can rotate evenly in the stator;

3. The bearing parts of the permanent magnet governor are formed by using forged steel lathe processing technology. Its main function is to fix the rotor so that the rotor cannot move axially and has the functions of storing lubricant and protecting the bearing;

4. The inter-pole support block is generally formed by a stainless steel milling machine, which can be used as a fixed tile magnet while making its magnetic field more uniform;

5. The wire mesh is made of iron wire, which can effectively prevent foreign matter from entering the permanent magnet governor.

◆Inner rotor part structure

When this part is rotating, cutting the magnetic lines of force will generate magnetic vortices to drive the outer rotor to rotate. It is usually made by lamination of 140 silicon steel sheets with a thickness of 0.5 mm and sleeved on the shaft to be concentric with the outer rotor.

okplazas.com is an electromechanical professional agent for sales of governor related products. Welcome to email: [email protected] for consultation, and you can also contact WeChat customer service +86-13689242098 online for product consultation!