Today, the editor of okplazas.com will tell you

Today, the editor of okplazas.com will tell you how to select the absolute encoder, the principle of absolute encoder selection, the absolute encoder is a rotating disc with several transparent and opaque windows, through the optical receiver Then the intermittent light beams are collected, the light pulses are converted into electrical pulses, then processed by the electronic output circuit, and the electrical pulses are sent out. The absolute encoder is unique in each position determined by the mechanical position. It does not need to remember, find a reference point, and is always calculating. It needs to know the location when needed, and read its location when needed. In this way, the anti-interference characteristics of the encoder and the reliability of the data are greatly improved.

shell material

For absolute encoders, the material of the housing is very important. It is not only the basis of the environmental adaptability of the encoder, but also the guarantee of various internal components.

Protection. With the improvement of current technology, the housing materials of encoders have begun to diversify. Nowadays, a major trend is to use rare earth alloys.

The gold material is used as the base of the shell. The advantage of rare earth material is that it has good strength and better sealing, which can help the equipment better

Adapt to different industrial environments. The details that need to be considered in the process of selecting the shell material are the shape and size.

Performance considerations

There are many items that need to be considered for the performance of an absolute encoder. The first is the signal conversion method. Different encoders have different characteristics in signal conversion. The encoder uses the internal rotating disk to divide it into four. The difference between each adjacent part is 90 degrees. This can help the device to obtain the signal direction more accurately while the signal measurement is converted. The signal can be well received through the groove during operation. The beam is hit on the rotating disk, and the signal parameters can be obtained through the pre-drawn partitions. In the process of absolute encoder design, the biggest difficulty is to make the connection between different signals and the rotating disk.

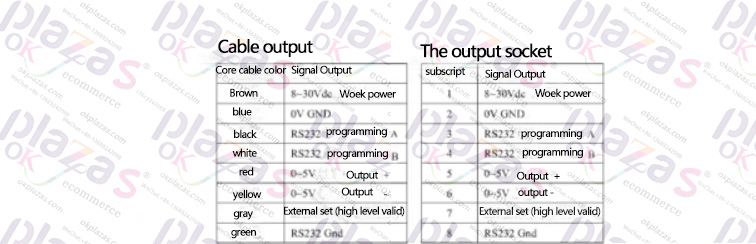

Wiring instructions (see the figure below)

1. High-power (referring to how much work the object does in a unit time) circuit uses power-type wirewound absolute encoder;

Second, the sound control (paraphrase: adjustment, control) system of the audio system can choose a straight sliding absolute encoder;

Three, the reference voltage adjustment of the power supply circuit should use a fine-tuning absolute value encoder;

Four, the absolute value encoder used in communication equipment and computer can choose the chip multi-turn absolute value encoder or single-turn absolute value encoder;

5. The volume adjustment and power switch of the semiconductor radio can choose a small binary encoder with a rotary switch;

6. High-precision wirewound absolute value encoder, precision multi-turn absolute value encoder or metal glass glaze absolute value should be used in circuits such as precision instruments and equipment

Encoder;

7. When selecting an absolute value encoder, the material, structure, type, and type of the resistor body of the absolute value encoder should be selected according to the specific requirements of the application circuit.

Specifications, adjustment methods and methods;

8. The absolute value encoder for sound control (paraphrase: adjustment, control) system in audio equipment should use reverse logarithmic (previously called exponential) absolute

Value encoder, absolute encoder for volume control can choose logarithmic absolute encoder;

9. After selecting the type and specification of the absolute encoder according to the requirements of the equipment and circuit, choose the absolute encoder reasonably according to the requirements of the circuit

The electrical parameters of the device include rated power, nominal resistance, allowable deviation, resolution, maximum operating voltage, dynamic noise, etc. Absolute encoder manufacturer

The code is determined by the mechanical position. It does not need to be memorized, no need to find reference points, and there is no need to keep counting. When do you need to know the position and when

Just go to read its location. In this way, the anti-interference characteristics of the encoder and the reliability of the data are greatly improved.

There are incremental encoders and absolute encoders in magnetoelectric encoders. Friends will require the number of digits when purchasing, for example: 11 bits, 12 bits, 13

Bit..., so are you clear about the principles of selection? Let's take a look at the relationship between the accuracy of the absolute encoder and the resolution.

The number of digits of a single-turn absolute encoder represents the number of code channels of the code disc. Because it uses a binary code disc (the same Gray code), its accuracy is

The number of powers of 2, such as 12 bits, is the 12th power of 2, which is 4096. The resolution and accuracy of the encoder are not necessarily the same, the accuracy varies with the reticle,

It is determined by various factors such as the mechanical concentricity of the encoder, the reading response speed, and temperature characteristics. If an encoder is subdivided with scribed sine wave to obtain high resolution

If the accuracy is not improved, the subdivision only improves the resolution. What is the accuracy of the reticle before subdivision, and what is the accuracy after subdivision,

So the accuracy of some high-resolution encoders depends on how many lines are used for subdivision. The current position data transmitted through SSI, the following "best

The "worst case" and "worst case" must be considered.

The output of position data depends on several parameters, such as: factor, conversion time, data format, etc. Therefore, the processing time will vary. use

You will "only" get an average response time for the processor system. If you use the highest frequency 500kHz to poll the SSI channel. Ie (pulse time

2µs*26 bits + minimum required pause time 40 microseconds) is the shortest time about 100µs. Thereafter, the system will require another 400-500µs time

Time is used for data update, so in the "worst case" you may get the same result (position value) three times! Only use faster DSP

Or ASIC you can get a shorter time (factor of 10), or use the encoder with SIN/COSINE code channel applied to the motor control system.

This kind of design is usually not too expensive (providing an encoder type that reduces some requirements): incremental encoder with cable connector, live

Absolute encoders and sealed enclosures for cable connectors (such as parallel single-turn, SSI or BiSS). It can be simplified if the number of pulses per revolution (PPR) is correctly selected

Calibration factor. Once PPR is selected, or just follow the formula in the technical manual. When choosing the calibration constant, remember that the closer to 1 the better.

The value of the calibration constant is the resolution of each pulse of your best encoder. For more exciting content, click on the precautions in the absolute encoder selection method to learn more.