What are the characteristics and advantages of plum coupling

What are the characteristics and advantages of plum coupling

What are the characteristics and advantages of plum coupling?

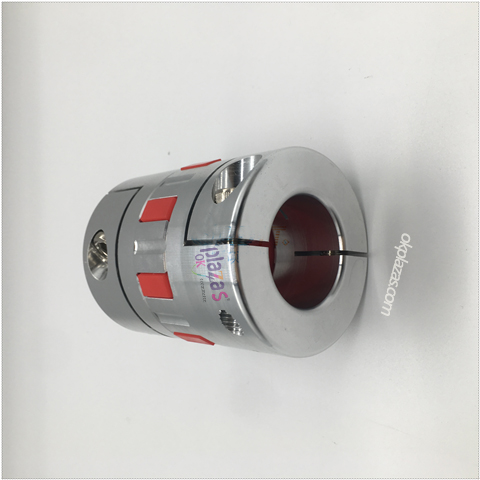

The quincunx coupling is also called the quincunx elastic coupling, which uses a quincunx-shaped elastic element to be placed between the two coupling halves to realize the coupling of the two halves. It has the characteristics of compensating the relative displacement of the two shafts, damping, buffering, small radial size, simple structure, no lubrication, high carrying capacity, and convenient maintenance.

First, the manufacturing process of plum coupling

The plum blossom coupling is processed by turning, milling, and broaching, and then undergoes overall heat treatment. In order to ensure sufficient mechanical strength, there is a claw-shaped plate on the market that can be mass-produced without processing losses. So in terms of price, it is much lower than mechanical processing, but the performance of castings is not very good, so it is best not to use it in some important occasions. In addition, the claw teeth of castings are prone to tooth chipping (claw teeth fall off) under high speed or high load conditions.

Second, the structure and characteristics of the plum blossom coupling

1. Compact, no backlash. Vibration reduction, radial and angular deviation compensation. The structure is simple, easy to maintain and inspect. Maintenance-free, oil-resistant, electrical insulation, working temperature 20℃-60℃; 5. Plum blossom elastomer has four petals, six petals, eight petals and ten petals. Fixing methods include top wire, clamping, keyway fixing, etc.

Third, the elastic body of plum coupling is generally made of engineering plastic or rubber.

The life of the coupling also depends on the life of the elastomer. Because the elasticity is compressed, the tension is obvious. The service life of the elastomer is generally 10 years. Because of its cushioning and damping effect, it is often used under strong vibration conditions. The performance limit temperature of the elastomer determines the operating temperature of the coupling, which is generally -35~80℃.

Fourth, the classification and characteristics of plum coupling

There are two main types of plum blossom couplings, one is the traditional straight claw type, and the other is the curve (concave) claw type zero-backlash coupling.

The traditional straight-jaw plum coupling is not suitable for high-precision servo drive applications. The zero-backlash claw-shaped plum blossom coupling is developed from the straight claw coupling, but the difference is that its design can be adapted to the application of the servo system. It is usually used to connect servo motors, stepping motors and ball screws. The function of the curved surface is to reduce the deformation of the elastic plum cushion block and limit the influence of centripetal force on it at high speed. The zero-backlash claw coupling consists of two metal sleeves (usually made of aluminum alloy or stainless steel) and a plum-shaped elastic gasket.

The plum blossom elastic spacer has multiple blade branches, and the zero-clearance elastic coupling makes it fit well with the slider. Different from the slider coupling, the plum blossom coupling is driven by extrusion, and the slider coupling is driven by shear force. When using a zero-clearance claw coupling, the user must be careful not to exceed the maximum bearing capacity of the elastic element given by the manufacturer (under the premise of ensuring zero clearance), otherwise the plum elastic gasket will be flattened and deformed and lose its elasticity. The pre-tightening force disappears, resulting in a loss of zero-clearance performance. After a serious problem occurs, users may find out.

The plum coupling has a good balance performance and is suitable for high-speed applications (up to 30,000 RPM), but it cannot handle large deviations, especially axial deviations. Larger eccentricity and deflection angle will produce greater bearing load than other servo couplings. Another noteworthy issue is the failure of plum coupling. Once the plum blossom elastic gasket is damaged or fails, the torque transmission will not be interrupted. At the same time, the metal claws of the two shaft sleeves mesh together to continue to transmit torque, which may cause problems in the system.

The plum blossom flexible coupling is suitable for connecting the two coaxial lines of the drive shaft system. It has compensation for the relative deviation of the two shafts, damping, wear resistance, and cushioning performance; the working temperature is -35℃~80℃, and the nominal transmission torque is 16- 25000n.M, allowable speed is 10900-1900r minimum, shaft hole diameter range is 14-140mm, shaft hole length is 42-252mm, shaft hole length is 42-252mm.

Fifth, the installation and removal of the plum blossom coupling

1. Wipe off the dust on the surface of the mounting shaft and apply a thin layer of oil or lubricant on it.

2. Clean the inner hole of the coupling and apply oil or lubricant.

3. Insert the coupling into the mounting shaft. If the hole diameter is too tight, be careful not to hit the installation with a hammer or hard metal.

4. First, use a torque wrench to tighten the screws diagonally between 14 and 41 with the specified tightening torque. 5 Increase the force and the specified tightening torque 12 and 41. Repeat step 4.

6. Tighten and fix according to the specified tightening torque.

7. Finally, tighten the fixing screws in the circumferential direction.

8.Please proceed when the equipment is completely stopped, and loosen the locking screws one by one.

The above is a relevant introduction about the characteristics and advantages of the plum coupling. I hope I can help you! okplazas.com is a high-tech enterprise integrating professional R&D, production and sales of high-precision couplings, mainly producing plum couplings. The company's products have passed CE certification and ROHS certification. Strength casts brand, professional achievement quality.