What are the functions of the hot air non-woven fabric defect detection system

What are the functions of the hot air non-woven fabric defect detection system

What are the functions of the hot air non-woven fabric defect detection system

Okplazas. com focuses on machine vision surface defect online detection system. It is an equipment supplier of internationally advanced high-speed sheet and coil surface defect online detection system. The company's core products include: film surface defect online detection system, non-woven stain detector, paper defect Online inspection system, strip surface defect inspection system, etc.

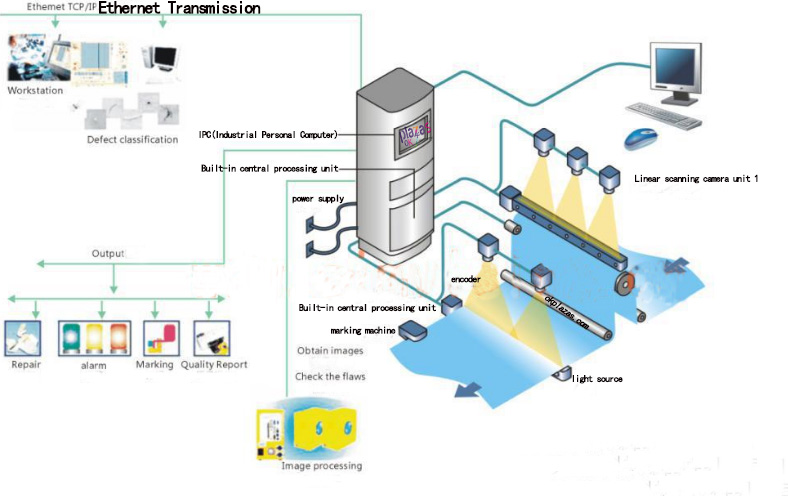

Nowadays, non-woven fabrics will produce many defects such as stains and nodes in the production process, which seriously affects product quality and corporate image. Okplazas. In response to this phenomenon, com research and production of non-woven fabric surface defect detection systems are mainly based on advanced machine vision technology, combined with the characteristics of non-woven fabrics sparseness and texture, using a combination of frontal irradiation and reverse projection imaging methods, which can perform high-speed online Accurate surface defect detection; combined with on-site process online alarm, automatic report statistics and product classification disposal, etc., provide an effective solution for the enterprise's production informatization and product quality.

Test object: Spunlace nonwoven fabric, heat-bonded nonwoven fabric, pulp airlaid nonwoven fabric, wet nonwoven fabric, spunbonded nonwoven fabric, meltblown nonwoven fabric, needle punched nonwoven fabric, stitched nonwoven fabric Spinning cloth and so on.

Detection principle: In view of the material characteristics of the non-woven fabric itself with uneven thickness, sparse and uneven structure, and the randomness of the defect distribution (the front, back and middle of the non-woven fabric), the traditional transmission lighting method is likely to cause the system to miss the inspection and False positives. The non-woven stain detector uses a shadowless bright field to form the detection environment, that is, one light source transmits under the material, and the other light source reflects above the material. When the production line starts to run, the CCD camera synchronizes according to the speed signal collected by the encoder Scanning and shooting, the collected images are dynamically segmented through image analysis software algorithms, and the grayscale differences between the flawed image and the normal product are used to find the flaws and perform alarm, statistics, classification, and recording operations.

System function

1. Real-time defect location distribution map display;

2. Real-time display of specific information of defect images;

3. The product batch number is automatically generated and the product batch number can be manually modified during the production process;

4. Establish a complete historical database query according to the product batch number;

5. The historical record automatically generates the reverse defect location distribution map corresponding to the batch number, which is convenient for later sub-volume;

6. Statistical generation and printing of information reports;

7. Real-time interception and display of defective pictures;

8. Long-term, large-capacity historical record storage;

9. Remote technical service (Note: The software function can be fully customized according to user requirements!)

The sales and installation service process of the non-woven fabric surface defect detection system is as follows:

1. According to the enterprise customer's field equipment environment, carry out the overall system plan design and quotation;

2. Determine the system hardware selection and testing software evaluation according to the design plan;

3. System equipment installation, online debugging and after-sales service.