What are the performance characteristics of the spindle encoder?

What are the performance characteristics of the spindle encoder?

What are the performance characteristics of the spindle encoder?

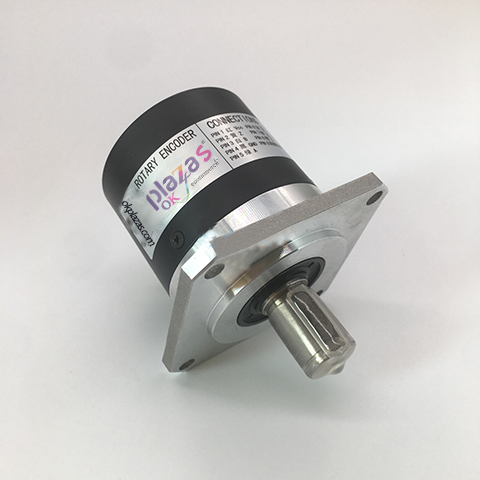

The machine tool spindle encoder contains several important technical index characteristics such as precision, resolution, repeatability and nonlinear error. The editor of okplazas.com will tell you what are the performance characteristics and precautions of the spindle encoder?

First, the accuracy of the spindle encoder

Accuracy refers to the level close to the bottom between the accurate measurement value and the actual value. Without comparison with the standard, there is no accuracy. The accuracy is determined by the basic error limit and influence of the controller, such as temperature changes, environmental humidity changes, switching power supply fluctuations, and frequency changes. The accuracy of the spindle bearing servo motor determines the total data error of the system software. Data errors usually include system software errors caused by various factors, such as non-linearity, delay, or cross-sensitivity to the office environment, such as temperature and vibration. According to the linearization solution, the system deviation can be partially or fully corrected. The accuracy of a servo motor is usually expressed by viewing angle or pitch. If the number of matching steps is an exponential multiple of 2,

The precision is usually expressed in the form of "ten digits". Note: "Ten digit" is the index value of 2.

Accuracy, such as: 14 digits = 120 arc seconds

Second, the resolution of the spindle encoder

Resolution is the smallest enterprise that can accurately display information or measurements. The resolution refers to the spindle bearing servo motor.

The smallest part that can be distinguished between conversion and step counting depends on the magnetic induction element used. Generally speaking, the method of fine differentiation can improve the resolution of the servo motor.

However, the noise of the data signal can be improved by fine differentiation. The resolution of the rotary encoder is generally expressed by the data signal output transformation of each rotation period of the shaft, or

Yes, the data signal output conversion of the linear servo motor matches the interval per millimeter. If the number of steps is an exponential multiple of 2, the resolution

Ratio is usually expressed in the form of "bits". The measurement of resolution is a key factor in measuring speed and instantaneous speed. Resolution, for example:

262144 steps = 18 bits = 5 arc seconds

Third, the repeatability of the spindle encoder

Repeatability refers to the ability to reproduce the same results without changing internal conditions. In some applications, repeatability is more critical than accuracy. This is because if the system software is repeatable, errors can be eliminated through compensation. The repeatability of the spindle bearing servo motor refers to the maximum deviation of the servo motor at a given position continuously and accurately measured five times. Generally speaking, repeatability represents any conversion value of the station data signal over time. This conversion value is usually caused by the noise of the electronic signal of the servo motor. According to signal analysis, noise can be reduced, but this will also reduce the network bandwidth of the servo motor output. Repeatability, such as: -7.2 arc seconds

Fourth, the nonlinear error of the spindle encoder

4. The input and output of the spindle bearing servo motor is 40, and the accurate measurement and result are & 41; respectively as the vertical axis and horizontal axis of the rectangular coordinate system, select the appropriate coordinates

, And coordinate the corresponding point

The IO is idealized into the coordinate system to obtain an ideal IO correlation curve. By putting the corresponding point of a specific IO into

Among the marks, a specific IO related curve can be obtained. In the most ideal case, these two graphs should overlap. In fact, it is impossible to guarantee that the distance between the two images is the error. If the two graphs are the same but do not overlap, for example, one graph is equal to the displacement of the other curve or the slope of a straight line, the error is linear, otherwise the error is nonlinear.