What happens when you scroll the mouse wheel Let's see how the encoder works

What happens when you scroll the mouse wheel Let's see how the encoder works

What happens when you scroll the mouse wheel Let's see how the encoder works

Have you ever encountered a situation where the mouse wheel fails?

When doing PPT, the page suddenly turns automatically, and the page is stuck and cannot slide up and down. These eight achievements are that the scroll wheel is broken.

So, do you know how the scroll wheel works? Why does it fail?

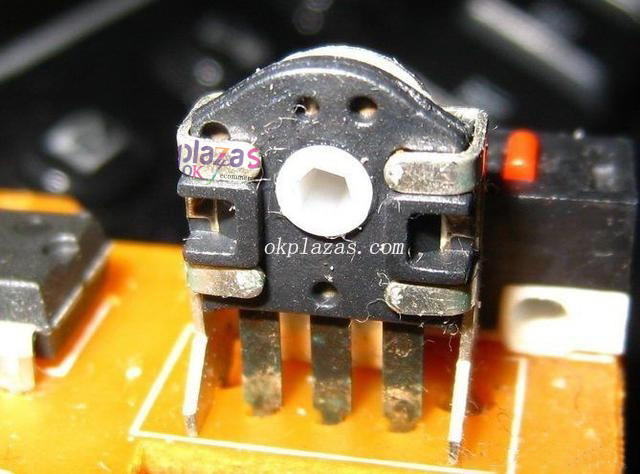

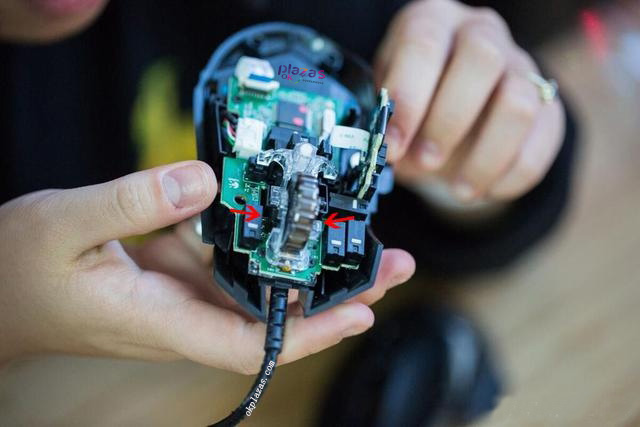

Most mouse wheels are related to this little thing, which is a rotary encoder switch, also called a mechanical encoder.

One end of the wheel is inserted into this turntable. When we roll the wheel, the turntable is driven to rotate and generates a pulse signal. The computer uses this signal to determine the direction and speed of the wheel.

Let's take a look at a mechanical encoder. It’s this little thing, it’s so simple. There are 4 parts in total.

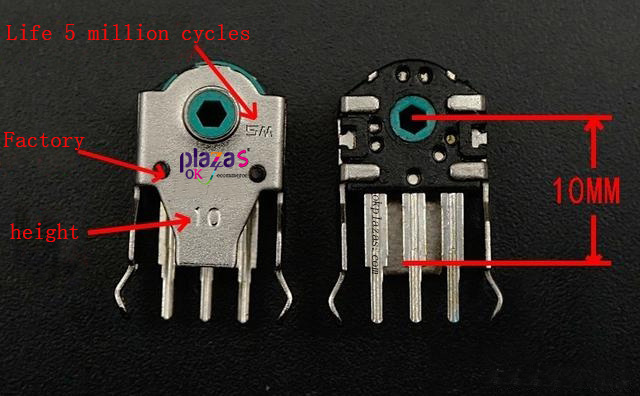

The iron case is on the far left. Generally, there will be manufacturer information, installation height, and service life on it.

For example, the manufacturer's curiosity, the installation height is 10 mm, and the life span is 5 million cycles.

It should be noted here that the installation height is measured according to the figure on the right.

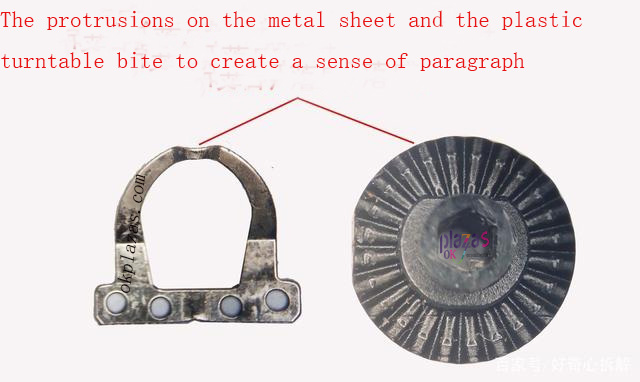

Then there is the shrapnel, and then to the right is the plastic turntable with scales.

When the turntable rotates, the side with the scale rubs against the shrapnel, creating a sense of paragraph. When we use the scroll wheel, there will be a feeling of grid by grid, which comes from the turntable and the shrapnel.

The other side of the turntable is inlaid with a contact piece with contacts. The 3 contacts are separated by 120 degrees each and are equally divided, corresponding to 3 fan-shaped areas.

On the far right is a plastic shell base with a copper sheet embedded in it. I don't know the scientific name, so let's call it copper sheet. This copper piece, measured with a multimeter, is actually 3 parts connected to 3 pins.

Note that the areas of these three fan-shaped regions are not the same, the red one is the largest, and the other two are equal.

We give these areas a number, red, yellow and blue correspond to 0 1 2

When the turntable rotates, the contact piece and the 3 copper pieces are alternately connected, disconnected, and continuously emit different signals.

This signal is processed by the mouse and transmitted to the computer. The computer judges the direction of the scroll wheel based on this signal.

If we also add the time unit, the computer can determine the speed of the scroll wheel.

We add the contact piece on the turntable. This green three-pronged pointer represents the contact piece.

Take clockwise rotation as an example.

As it rotates, different signal combinations appear.

0 02 012 01 02 012 01 02

When the computer receives this signal, it will determine that the mouse has made a clockwise rotation within a certain unit of time.

By analogy, if the computer receives a signal that is arranged in the reverse direction, it means that the scroll wheel is rotating counterclockwise.

This is the working principle of a mechanical encoder.

Seeing this in the video, everyone here is basically half a peripheral expert. You must have guessed why the scroll wheel breaks so easily, right?

The mouse itself is a consumable, so based on cost considerations, most mice on the market use mechanical encoders. Inside the encoder, the various frictions of metal and plastic have a natural short life. In order to reduce the cost, it is really only worse than the worst. The shrinkage of the material leads to a linear decline in the feel, life and other aspects. These commercially available mechanical encoders are marked with a lower life of 50,000 cycles, and the higher ones are called 2 million cycles. The price ranges from a few mao to a few yuan. If it is damaged, given the metal structure inside, I personally think it has no repair value. If it is broken, just replace it with a new encoder.

Curious students will definitely ask, since most of the mice use mechanical encoders just now, what about the small part?

This small part refers to the grating wheel.

Then let's take a look at the grating.

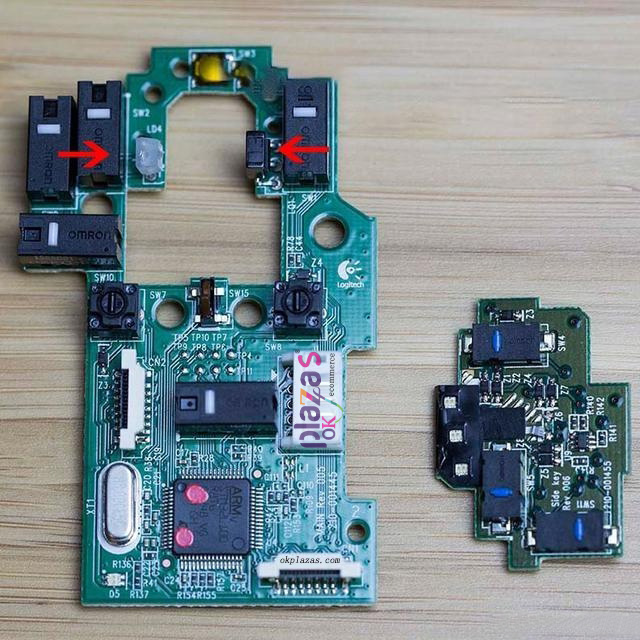

First look at this roller, there are many grids in the middle of the roller, these grids are gratings. On both sides of the scroll wheel are light sources and sensors. When the scroll wheel rotates, it will repeatedly block/transmit light. The chip calculates the moving direction and speed of the scroll wheel based on the flashing of light and shadow.

This is the principle of the grating roller.

So which one is easy to use?

Let me talk about my personal feelings, just for reference. Under the same product level, grating rollers are slightly more expensive than mechanical rollers.

Since the main components of the grating encoder are non-contact when in use, the inherent life is extremely long

The grating rollers are afraid of light interference. I don’t seem to see any roller with a grating with a marquee.

The structure of the grating roller is more complicated, and generally heavier.

Finally, it’s the hand feeling. The grating’s hand feeling is more stable. The mechanical scroll wheel’s hand feeling is too dependent on the encoder. After all, the friction between plastic and metal will always age over time.

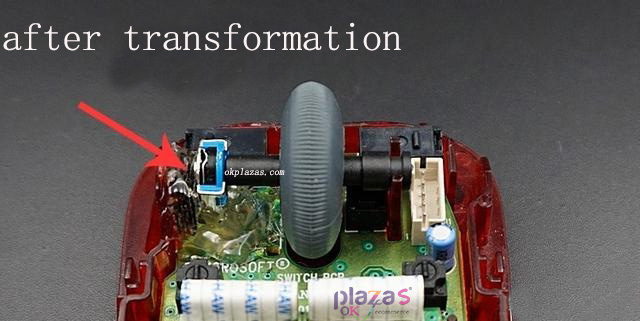

In fact, we can't say who is good and who is bad. We often see the great god changing Microsoft's IE mouse from a grating to a mechanical scroll wheel.

Speaking of the scroll wheel can have an optical scroll wheel, can the micro movement also have an optical micro movement?