What is a coupling What are the functional applications of the coupling

What is a coupling What are the functional applications of the coupling

What is a coupling What are the functional applications of the coupling

What is a coupling? What are the functional applications of the coupling?

Coupling is a device that connects two shafts or two shafts with rotating parts, and rotates together in the process of transmitting motion and power, and does not separate under normal conditions. Sometimes it is also used as a safety device to prevent the connecting parts from being subjected to excessive loads and play a role in overload protection.

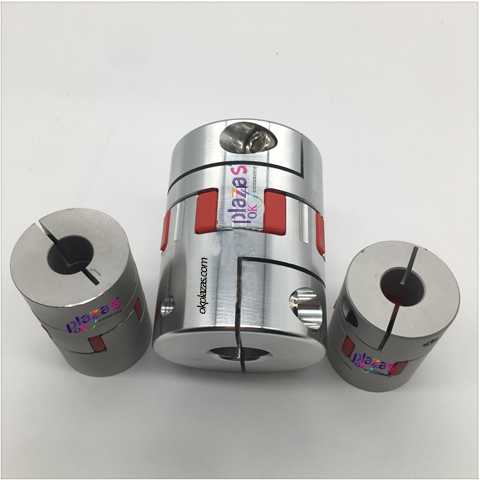

The coupling is also called the coupling. It is a mechanical component that connects the driving shaft and the driven shaft of different mechanisms to rotate together and transfer motion and torque. Sometimes it is also used to connect shafts with other components (such as gears, pulleys, etc.). It usually consists of two parts, which are respectively connected by a key or a tight fit, fixed on the ends of the two shafts, and then the two halves are connected in some way. The coupling can also compensate for the offset between the two shafts (including axial offset, radial offset, angular offset or comprehensive offset) caused by inaccurate manufacturing and installation, deformation or thermal expansion during operation, and ease Impact and vibration absorption.

Most commonly used couplings have been standardized or standardized. Under normal circumstances, you only need to select the correct coupling type and determine the coupling type and size. When necessary, the bearing capacity of the weak link can be checked and calculated; when the speed is high, the centrifugal force of the outer edge and the deformation of the elastic element should be checked and calculated to check the balance.

Due to manufacturing, installation, load deformation and temperature changes, it is difficult to maintain strict and accurate alignment of the two axes after installation and adjustment. There is a certain displacement and deflection angle CI in the X and Y directions. When the radial displacement is large, a slider coupling can be used, and the two shafts with a large angular displacement or intersecting can be connected by a universal coupling. When the two shafts produce a large additional relative displacement during the working process, a flexible coupling should be used.

What is a coupling? What are the functional applications of the coupling? Classification and working principle of commonly used couplings, selection of commonly used couplings, introduction to the role of couplings in practical applications

Here are several commonly used couplings

Universal coupling

The working speed of the coupling and the resulting centrifugal force. For high-speed drive shafts, couplings with high balance accuracy, such as diaphragm couplings, should be used instead of eccentric slider couplings.

The classification and working principle of the coupling, the choice of the coupling, the function of the coupling at the end

Sliding coupling

The size and nature of the transmitted torque and the requirements of the damping function. For example, for high-power and heavy-duty transmissions, gear couplings can be selected; for transmissions with large impact loads or to eliminate shaft torsional vibration, high-elastic couplings such as tire couplings can be selected.

What is a coupling? What are the functional applications of the coupling?

The working speed of the coupling and the resulting centrifugal force. For high-speed couplings, such as high-speed couplings, diaphragm couplings should not be used.

Diaphragm coupling

The magnitude and direction of the relative displacement of the two axes. When it is difficult to align the two shafts strictly and accurately after installation and adjustment, or when the two shafts will have a large additional relative displacement during the working process, a flexible coupling should be used. For example, when the radial displacement is large, a slider coupling can be used, and the two shafts with a large angular displacement or intersecting can be connected by a universal coupling.

What is the reliability and working environment of the coupling

In general, non-lubricated couplings made of metal parts are relatively reliable, and the performance of couplings that require lubrication are easily affected by the degree of lubrication perfection and may pollute the environment. Couplings containing non-metallic parts such as rubber are sensitive to temperature, corrosive media and strong light, and are prone to aging.

What is a coupling? What are the functional applications of the coupling?

Sliding coupling

The manufacturing, installation, maintenance and cost of the coupling. Under the premise of satisfying convenience and performance, couplings with convenient installation and disassembly, simple maintenance and low cost should be selected. For example, the rigid coupling is not only simple in structure, but also easy to disassemble and assemble, and can be used for low-speed, rigid drive shafts. General non-metallic elastic element couplings (such as elastic sleeve pin couplings, elastic pin couplings, plum-shaped elastic couplings, etc.) are widely used in general medium and small power transmissions due to their good comprehensive performance .

The above is about what is the coupling? What are the functional applications of the coupling? Introduction of related knowledge. okplazas.com is a high-tech enterprise integrating R&D, production and sales of industrial encoders and high-precision couplings. okplazas.com focuses on encoders, electronic handwheels, coupling series; German technical standards, precision casting, export quality! Welcome everyone to communicate and learn together!