What is the difference between a turret milling machine and a vertical milling machine

What is the difference between a turret milling machine and a vertical milling machine

What is the difference between a turret milling machine and a vertical milling machine

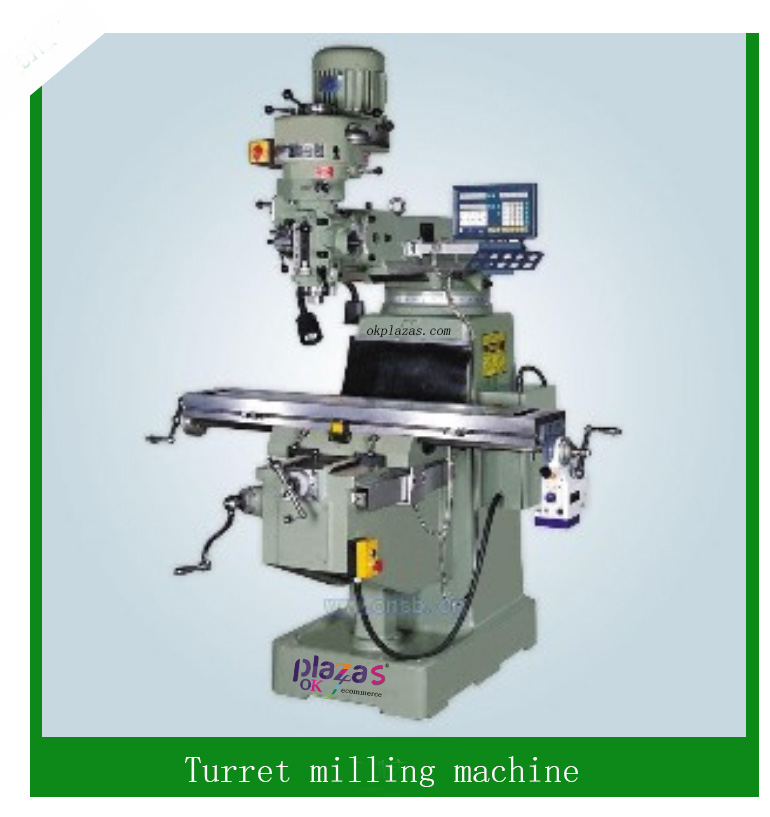

Turret milling machine refers to a machine tool with a worktable that drives the workpiece to move, and a high-speed spindle drives the tool to rotate for cutting. The shape is similar to a turret. Turret milling machine is also called radial arm milling machine, radial arm milling, universal milling. Turret milling machine has compact structure, small size and high flexibility. The milling head can rotate 90 degrees from left to right and 45 degrees back and forth. The rocker arm can not only extend back and forth, but also rotate 360 degrees in the horizontal plane, which greatly improves the effective working range of the machine tool. . QXJH2 type tilt sensor is installed inside.

Vertical milling machine The vertical milling machine uses a vertical head to process the workpiece, which is suitable for processing larger planes and processing grooves and step planes with various shank milling cutters. The milling head can be adjusted ±45° clockwise and counterclockwise in the vertical plane, and the DWQT type angle sensor is installed inside.