What problems should be paid attention to when installing the servo motor encoder?

What problems should be paid attention to when installing the servo motor encoder?

What problems should be paid attention to when installing the servo motor encoder?

What problems should be paid attention to when installing the servo motor encoder?

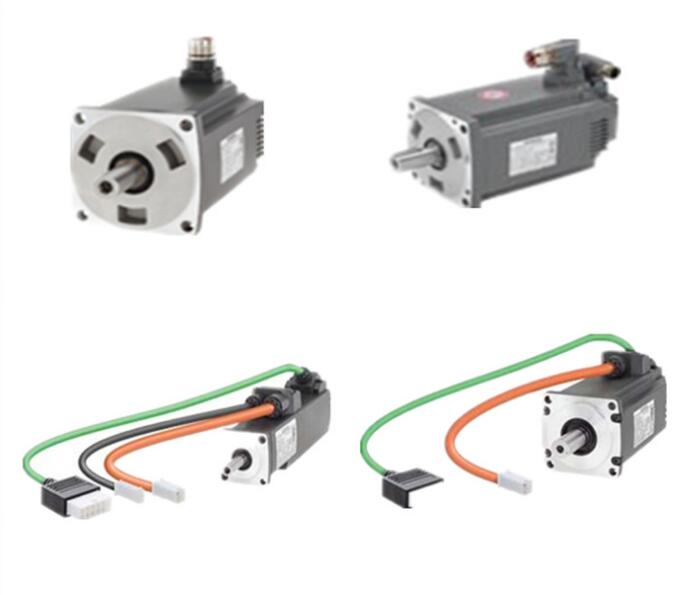

The sensor on the servo motor that measures the magnetic pole position and the rotation angle and speed of the servo motor is called the servo motor encoder. It will not directly hit the shaft during installation. The encoder shaft of the servo motor manufacturer should be connected to the machine and a flexible connector should be used. When installing the connector on the shaft, do not press hard. Even if a connector is used, a load greater than the allowable load may be added to the shaft, or the iron core may be pulled out due to improper installation.

Bearing life is related to operating conditions, especially affected by bearing load. If the bearing load is less than the specified load, the bearing life can be greatly extended. Do not disassemble the encoder, otherwise the oil resistance and drip resistance will be damaged. Do not immerse the anti-drip agent product in water for a long time. When there is water or oil on the surface, wipe it clean.

In the actual application on site, we will encounter various problems in the installation, including mechanical and electrical aspects. If you do not pay attention or do it irregularly, it will affect the normal use and life of the encoder. The following instructions The detailed instructions on the installation of TECO servo motor encoder are more helpful to our application experience.

Each electrical interface has its own characteristics, as well as different baud rates and transmission distances, which can be selected according to the specific application environment of the site, the actual transmission distance and transmission rate, the installation interference environment of the encoder and communication cables, grounding, and wiring. The selection of cable material has a lot to do.

The wires of the okplazas.com servo encoder should be connected according to the electrical instructions in the parameter table. The wires that are not used should be individually insulated or wrapped or an insulating sleeve should be added to avoid damage to the encoder due to short-circuit with other signals or power wires. The electrical wiring of the okplazas.com servo encoder must be done when the power is completely cut off. The encoder is easily damaged by plugging and unplugging the connector or cable.

First, the electrical interface:

Each electrical interface has its own characteristics, as well as different baud rates and transmission distances, which can be selected according to the specific application environment of the site, the actual transmission distance and transmission rate, the installation interference environment of the encoder and communication cables, grounding, and wiring. The selection of cable material has a lot to do. Each electrical interface has its own characteristics, as well as different baud rates and transmission distances, which can be selected according to the specific application environment of the site, the actual transmission distance and transmission rate, the installation interference environment of the encoder and communication cables, grounding, and wiring. The selection of cable material has a lot to do.

Second, electrical installation:

In the actual application of the servo motor field, we will encounter various problems in the installation, including mechanical and electrical aspects. If you do not pay attention or do it irregularly, it will affect the normal use and life of the encoder. The following The instructions are described in detail on the installation, which is more helpful to our application experience.

Third, the layout of vitality parts:

When the encoder is installed in the field, it cannot be installed with high interference source equipment such as frequency converter, transformer, solenoid valve, etc., keep a distance of 10cm, or install a metal partition to isolate it. The module that communicates with the encoder, when installed in the electrical cabinet, cannot be installed with high interference source components such as inverters, contactors, or frequently-opening switching components, keep a distance of 3cm, or install metal partitions Come to isolate.

Fourth, grounding protection:

The shielding layer of the cable should be grounded at the signal receiving end to prevent the leakage current between the two grounding points from damaging the cable; if the shielding of the cable cannot achieve good grounding protection, a separate grounding wire needs to be connected. Shield; when grounding long-distance connection, you need to add a yellow-green wire between the product shell and the grounding point as an equipotential compensation line; the shielded cable must be connected to the metal shell of the electrical component (encoder or electrical cabinet) at both ends, and ensure Connect correctly and touch the metal surface over a large area.