Eltra Encoder ER63G4096Z5L15X3PR

Description

ER 63 encoder series (ø 63.5 mm) with blind hollow shaft for industrial environments that require excellent mechanical resistance and high resolution (up to 24,000 ppr with zero).

Technical features

Outside diameter (max) 63.5 mm

Shaft diameter (max) 15 mm

Resolution (max) 24,000 ppr

Output frequency (max) 500 kHz

Operating temperature (° C) -20 ° ... + 70 °

Degree of protection IP 66

Extra / User Manual

INSTRUCTIONS OF

INSTALLATION

ER 63 G

This device must be powered by

a Class 2 or throttled power supply

voltage / current

Input voltage: + 30V DC max

Input current: 0.5A max

Complete documentation available on www.eltra.it

PRECAUTIONS FOR INSTALLATION AND USE

- The transducer must be used in accordance with its specifications. The transducer is an instrument of

precision measurement and is not a safety device.

- The assembly and commissioning of the device must be carried out by qualified personnel e

follow the installation instructions carefully. We strongly recommend that you avoid any changes

mechanical or electrical for safety reasons, the guarantee will be void in case of any modifications.

- Do not expose the device to stresses or impacts that may not guarantee correct operation.

- Make sure that the mechanical coupling of the transducer shaft is designed with the appropriate ones

elastic joints, especially in the case of excessive axial or radial movements.

- Check that the operating environment is free from corrosive agents (acids, etc.) or non-substances

compatible with the device and its IP protection degree.

- Check the connection of the device to earth; if necessary, provide an external connection

additional.

- Products with variant code (a number or combination of numbers after “.”) May have

mechanical and electrical connections different from the standard product. Refer to the documentation

additional.

- Installation and wiring must be performed by trained and powered personnel

OFF.

- To avoid short circuits, insulate unused wires at different lengths; don't use pins not

of the connector.

- Before powering the device, check the applicable voltage range.

- Route power and signal cables to avoid capacitive or inductive interference

could cause device malfunctions. Also route the transducer cable

away from power lines or any other cables with high noise levels.

- The user who integrates the transducer into his device must comply with CE regulations and is

responsible for the CE marking of the machine / fi nal device.

- Malfunctions due to failure to observe these precautions for use and installation

will result in the loss of the warranty.

- Eltra holds itself free from any liability for damage or injury due to non-compliance with

these directives.

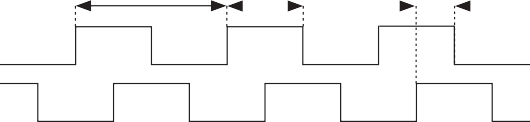

EXIT SIGNS

Frequenza= rpm x risoluzione

60

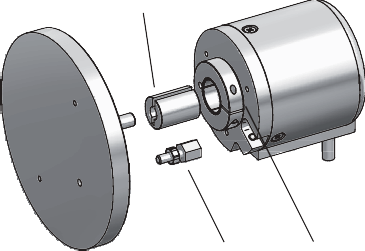

- Couple the reduction bushing (if present) 1 to the encoder shaft.

2.Screw the anti-rotation pin 2 onto the customer's engine flange with wrench n.8, then fasten it with the nut with wrench n.7

- Couple the encoder shaft with the motor shaft making sure that the pin is inserted into the groove (keep a minimum distance of 0.5 mm from the groove bottom, see figure A).

4.Fix the ring nut 3 using the appropriate screw (2.5 Allen key), recommended tightening torque

63 G

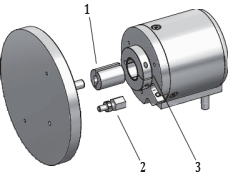

1.Apply the shaft adapter 1 (if present) to the encoder shaft.

2.Screw the torque pin 2 on the customer motor flange with key n.8, then secure it with the nut with key n.7.

3.Apply the encoder on the customer motor shaft, making sure the pin is inserted in the hole on the front part of encoder, maintaining a minimum distance of 0,5 mm, see Figure A.

Fix the collar clamping 3 with an HEX key 2,5; fixing torque 1,5 Nm / 212 Ozin recommended.