ABB soft starter PSE fault code and troubleshooting

ABB soft starter PSE fault code and troubleshooting

ABB soft starter PSE starting problems and failures

◆Fault status: LED is off and LCD is blank.

Cause: The power supply voltage Us is not connected.

Remedy: Refer to Chapter 5 Wiring and Chapter 11 Circuit Diagram of ABB Soft Starter PSE Installation and Commissioning Manual for wiring.

◆Fault status: Green LED is steady or flashing and LCD is dim.

Cause: The LCD backlit display automatically turns off.

Remedy: Press any key on the keyboard to recover.

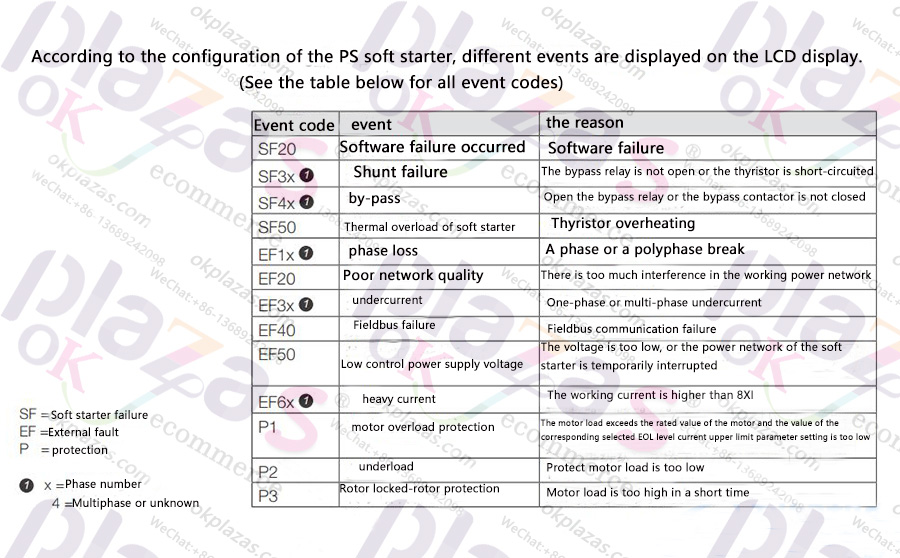

ABB soft starter PSE trip event failure

PSE fault indication code for ABB soft starter

◆ Software fault state: red fault LED stable bright or flashing and LCD fault code SF20.

Cause: Software failure.

Exclusion methods:

1. Disconnect and reconnect the control power supply voltage Us to restart;

2. If the problem still exists, please contact ABB low-voltage Department.

Cause: Soft starter parameter failure.

Exclusion methods: Check the PSE parameter and select the PSE soft starter type that corresponds to it.

◆ Bypass failure status: red fault LED stability bright and LCD failure code SF3x.

Reason: The by-pass contact is PSE18 closed after transportation (applicable only. PSE170).

Exclusion methods: Check the PSE parameter and select the PSE soft starter type that corresponds to it. Control the supply voltage at terminals 1 and 2, wait for four seconds, then switch on the main loop voltage at terminals L1, L2 and L3.

Cause: Bypass contactor/relay not on.

Elimination method: Check and replace the relay. Please contact ABB low voltage department for replacement.

Cause: Short circuit in SCR.

Method of exclusion: Check and replace the SCR. Please contact ABB low voltage department for replacement.

◆ Bypass disconnected state: red fault LED stability bright and LCD fault code SF4x.

Cause: Insufficient capacity of control power supply circuit.

Elimination method: Check the control supply voltage.

Cause: Bypass relay/contactor on or off.

Elimination: Check and replace relay or contactor. Please contact ABB low voltage department for replacement.

◆ Thermal overload status of soft starter: red fault LED stability bright and LCD fault code SF50.

Cause: the THYristor overheats, if the fault still exists after reset, and the thermistor temperature is too high.

Exclusion methods:

1. Check whether the fan works normally;

2. Check whether the cooling and ventilation channels are blocked by debris and dust;

3, check whether the ambient temperature is too high, more than 40 degrees need melting;

4. Check whether the installation Angle exceeds 30 degrees;

5. Check the number of times of STARTING and stopping of ABB soft starter PSE within an hour, whether it meets the requirements.

◆ Phase failure state: red fault LED stability bright and LCD fault code EF1x.

Cause: Fuse blown.

Method of elimination: Check and replace the three-phase fuse.

Cause: Loss of one - or multiphase working current.

Method of elimination: Check and ensure the normal operation of grid voltage.

Cause: Main circuit contactor or circuit breaker is disconnected.

Exclusion methods: Check and close contactor/circuit breaker or any external switching equipment.

Cause: The main contactor was broken prematurely during shutdown.

Exclusion methods:

1. Control the main loop contactor with terminal 4(operation signal);

2. Increase the delay time before the contactor is broken;

3. If the soft stop function of ABB soft starter is not needed, please set the buck time to 0.

◆ Poor state of power grid quality: Red fault LED stable bright and LCD fault code EF20.

Cause: Excessive interference of power supply network at work.

Method of elimination: Check and ensure the normal operation of grid voltage.

Cause: All three-phase working voltage is missing.

Method of elimination: Check and ensure the normal operation of grid voltage.

◆ Current missing fault status: red fault LED stable bright and LCD fault code EF3x.

Cause: operating current is too low, or missing in one or multiple phases.

Method of elimination: Check and ensure the normal operation of grid voltage.

Cause: Phase loss on the power side or motor side.

1. Check and provide the correct working power grid; 2. See phase failure EF14 for details.

Cause: The thyristor does not conduct.

Exclusion methods: Check and replace printed circuit board/SCR, contact local ABB low voltage department for replacement.

Cause: Motor load is too small (current is out of the range measured by ABB soft starter PSE).

Method of elimination: Check whether the soft starter conforms to the motor power.

◆ Bus fault state: red fault LED stability bright and LCD fault code EF40.

Cause: Bus wiring or bus adapter attachment failure.

Exclusion methods:

1. Check whether the bus adapter model used is correct;

2. Check whether the bus adapter is connected correctly;

3. Check whether the bus attachment is connected correctly;

4. Reset all existing events.

Cause: Bus communication not working.

Exclusion methods:

1. Check whether the bus adapter model used is correct;

2. Check whether the bus adapter is connected correctly;

3. Check whether the bus attachment is connected correctly;

4. Reset all existing events.

Cause: PLC not working.

Exclusion methods: 1. Adjust PLC to operation mode; 2. 2. Check the CONFIGURATION of PLC.

Cause: System bus control parameters without a bus are turned on.

Exclude method: Set the bus control parameter to close.

◆ Low power supply voltage state: red fault LED stable bright and LCD fault code EF50.

Cause: The soft starter control supply voltage is too low at terminals 1 and 2.

Elimination method: Check and provide the correct control supply voltage.

Cause: The control power supply network is temporarily missing.

Elimination method: Check and control the power supply network.

◆ High-current fault status: red fault LED stable bright and LCD fault code EF6x.

Cause: Operating current higher than 8*Ie.

Exclusion methods:

1. Check whether the motor is blocked or has difficulty in operation;

2. Check motor bearings and connectors;

3. Check whether the motor load is too heavy;

4, check the insulation on the motor winding;

5. Replace the motor.