Compatible use method of Siemens PLC high speed counting module and encoder

Compatible use method of Siemens PLC high speed counting module and encoder

Compatible use method of Siemens PLC high speed counting module and encoder

Compatibility of high-speed counting module and encoder

The high-speed counting module is mainly used to evaluate various pulse signals connected to the module, and to count and measure the pulse signals output by the encoder. The entire series of Siemens SIMATIC S7 products have modules that support high-speed counting, which can be adapted to various applications in different occasions.

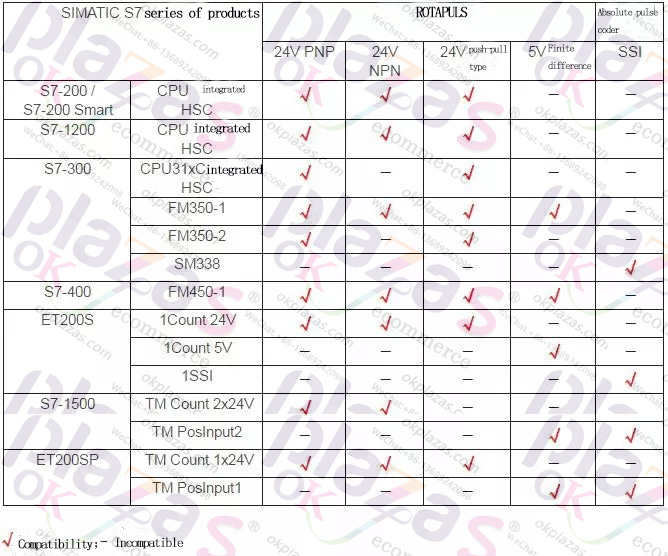

According to different product functions, the input signal types supported by the high-speed counting function of each product are also different. Pay special attention to the system design or product selection. The following table shows the compatibility information of Siemens high-speed counting products and encoders for reference when selecting models.

Compatibility of high-speed counting products and encoders

Common problems of encoder

1. Which parameters should be considered when selecting the encoder. When selecting the encoder, the following parameters can be considered comprehensively: Encoder type: Determine whether to choose an incremental encoder or an absolute encoder according to the application and control requirements. Output signal type: For incremental coding, determine the output interface type (source type, sink type) as needed.

Signal voltage level: Confirm the voltage level of the signal (DC24V, DC5V, etc.). Maximum output frequency: Confirm parameters such as the maximum output frequency, resolution, and number of bits according to the application and requirements.

Installation method and dimensions: comprehensively consider the requirements of installation space, mechanical strength, shaft state, appearance specifications, and mechanical life.

2. How to judge the quality of the encoder

There are several ways to judge the quality of the encoder:

Connect the encoder to the PLC's high-speed counting module, and judge whether the encoder output is correct by reading the actual pulse number or code value.

Check the output waveform of the encoder through an oscilloscope, and judge whether the encoder is normal according to the actual output waveform.

Use the voltage file of the multimeter to measure the encoder output signal voltage to determine whether the encoder is normal. The specific operation method is as follows:

1) When the encoder is NPN transistor output, use a multimeter to measure the voltage between the positive pole of the power supply and the signal output line. When the output voltage is close to the supply voltage when the output voltage is turned off, the output voltage is close to 0V. 2) When the encoder is PNP transistor output, use a multimeter to measure Measure the voltage between the negative electrode of the power supply and the signal output line when the output voltage is close to the supply voltage when the output voltage is close to 0V

3. Reasons for inaccurate counting and corresponding avoidance measures. In practical applications, there are many reasons for inaccurate counting or measurement. The following points should be paid attention to:

The environment where the encoder is installed is jittery, and there is looseness between the encoder and the motor shaft, and it is not tightly fixed.

The rotation speed is too fast, exceeding the maximum response frequency of the encoder.

The pulse output frequency of the encoder is greater than the highest input pulse frequency of the counter.

Interference occurred during signal transmission.

Measures to avoid the above problems:

Check the mechanical installation of the encoder, whether it is slipping, tooth skipping, whether the gear backlash is too large, etc.

Calculate whether the maximum pulse frequency is close to or exceeds the limit value.

Ensure that the maximum pulse frequency that the high-speed counting module can receive is greater than the pulse output frequency of the encoder.

Check whether the signal wire is too long, use a shielded twisted pair, ground it as required, and take necessary anti-interference measures.

4. How to deal with the idle encoder signal line

In actual applications, you may encounter signal lines that are not needed or supported by the module, such as:

For AB quadrature encoders (A, B, N) with zero signal, the module does not support N-phase input or does not require Z signal.

For differential output signals (A, /A, B, /B, N, /N), the module does not support the input of reverse signals (/A, /B, /N).

For these signal lines, no special treatment is required, and you can just give up!

5. Can multiple evaluations of incremental signals increase the counting frequency?

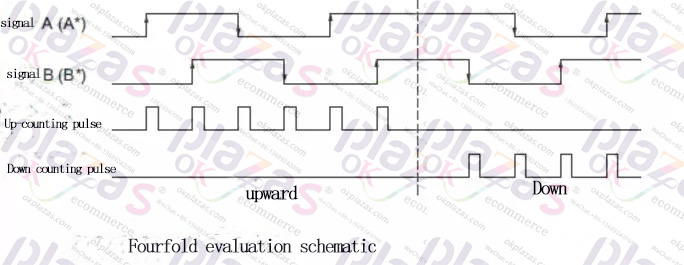

For incremental signals, multiple evaluation modes can be configured, including double evaluation and quadruple evaluation. Quadruple evaluation refers to judging the positive and negative edges of signals A and B at the same time to obtain the count value, as shown in Figure 4-1. For the quadruple evaluation mode, because a pulse is processed four times (four evaluations), the count value read is four times the actual input pulse number. The measurement resolution can be improved through multiple evaluations of the signal .

Through the above analysis of the principle of multiple evaluation of incremental signals, it can be seen that multiple evaluation only doubles the count value on the basis of the original count pulse, but actually has no effect on the actual input pulse frequency, so it will not increase the module. The maximum counting frequency. For example, the maximum counting frequency of FM350-2 is 10kHz, so even if it is configured in the quadruple evaluation mode, its maximum counting frequency is still 10kHz.