Do you know how to connect the encoder?

Do you know how to connect the encoder?

The main function of the encoder is that it is a rotary sensor that converts the rotational displacement into a series of digital pulse signals. These pulses can be used to control the angular displacement. If the encoder is combined with a gear bar or a spiral screw, it can also be used Measure linear displacement. Do you want to know the wiring method of 5-wire encoder? Add WeChat GKWEIXIU to pull you into the industrial control circuit board inverter maintenance exchange group. If you want to learn more about industrial circuit boards, elevator circuit boards, and inverters, please pay attention to "Inverter Repair from Scratch".

1. Wiring method:

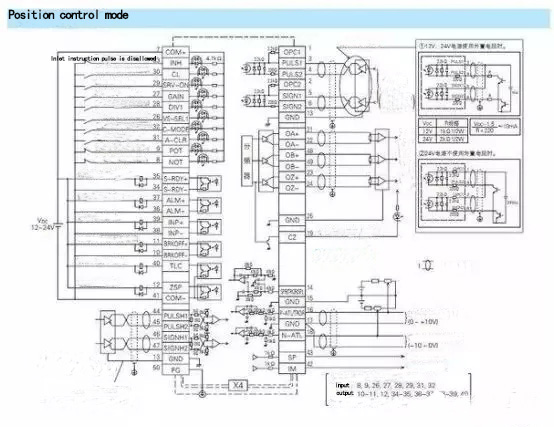

The encoder has 5 leads, of which 3 are pulse output lines, 1 is the COM terminal line, and 1 is the power line (OC gate output type). The power supply of the encoder can be an external power supply, or directly use the DC24V power supply of the PLC. The “-” terminal of the power supply should be connected to the COM terminal of the encoder, and the “+” terminal should be connected to the power terminal of the encoder. The COM terminal of the encoder is connected to the PLC input COM terminal. The A, B, and Z phase pulse output lines are directly connected to the input terminal of the PLC. A and B are pulses with a difference of 90 degrees. The Z-phase signal can only be rotated once the encoder A pulse is usually used as the basis for the zero point. Pay attention to the response time of the PLC input when connecting. The rotary encoder also has a shielded wire, which should be grounded when using it to improve anti-interference.

5 wire encoder wiring method:

1. The program uses a one-way counter to connect to a DC24V power supply and an A;

2. If you are using a bidirectional counter, connect the DC24V power supply and A and B. It should be noted that A and B need to be connected to the input point of the PLC with high-speed counting function;

3. The three cores are connected to +, -, and A phases. Follow the encoder manual to connect.

The 5 wires are A/B/Z, plus two power wires; the 5 wires are incremental and wire-saving encoder cables, including quadrature encoding, motor zero and power wires for common ground transmission, and sector Huo The Er signal is shared with ABZ, and is occupied by UVW for a short time when power is on; 5 programs are processed slightly, and the encoder power supply must be controlled when starting, and the number of cable cores is less than that of the multi-wire type.

2. Working principle:

A photoelectric code disc with an axis in the center, on which there are circular and dark engraved lines, is read by photoelectric transmitter and receiver, and obtains four sets of sine wave signals combined into A, B, C, D, each sine wave A phase difference of 90 degrees (360 degrees relative to a cycle), the C and D signals are reversed and superimposed on the A and B phases to enhance the stable signal; in addition, a Z-phase pulse is output every revolution to represent the zero reference Bit.

Since the phases A and B differ by 90 degrees, the encoder's forward and reverse rotation can be judged by comparing the phase A or the B phase. The zero reference position of the encoder can be obtained through the zero pulse. The materials of the encoder code disc are glass, metal, plastic. The glass code disc is deposited on the glass with very thin scribe lines, which has good thermal stability and high precision. The metal code disc is directly engraved with through and impassable lines and is not fragile. However, due to the certain thickness of metal, the accuracy is limited, and its thermal stability is one order of magnitude worse than that of glass. Plastic code discs are economical, and their cost is low, but accuracy, thermal stability, and life are worse.

Resolution—The number of open or dark engraved lines provided by the encoder per 360 degrees of rotation is called resolution, also called resolution indexing, or directly called the number of lines, generally 5 to 10,000 lines per revolution.