Introduce how to choose absolute encoder for heavy machinery and equipment

Introduce how to choose absolute encoder for heavy machinery and equipment

Introduce how to choose absolute encoder for heavy machinery and equipment

1. Type selection, first determine whether to use an incremental encoder or an absolute encoder according to the application needs, and whether to use a single-turn absolute encoder or a multi-turn absolute encoder for the absolute encoder.

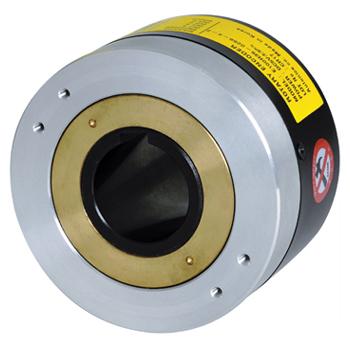

2. Appearance installation, according to the installation requirements of the mechanical equipment, select the encoder mounting flange form, the encoder has a shaft type or a sleeve type installation method.

3. Working environment and encoder level. Encoders are generally divided into chip level (required for secondary development before use), economic level (only for small equipment single use), standard industrial level (various equipment, outdoor equipment, various Kinds of automation engineering projects), special industrial requirements. The encoder grade should be selected according to the actual working conditions. In most cases of large and heavy machinery and equipment, the standard industrial grade should be selected.

4. Signal selection, according to the signal interface of its existing encoder receiving device, select the matching absolute encoder signal output interface. Analog signal, digital signal selection, parallel, serial, bus selection.

The choice of signal should take into account the convenience of on-site service and maintenance of large and heavy machinery and equipment. Compared with years of experience, the output of 4--20mA analog current signal is most popular with this type of equipment: it is more resistant to voltage-type signals. Interference is more convenient than digital signals. A multimeter electrician can check the signal on site. The convenience of choice is to save money.

5. Resolution and range (number of turns), according to the application needs, select the resolution (number of digits) of each turn of the encoder and the requirements of the measurement stroke (number of turns).

6. Performance guarantee, temperature grade, anti-vibration grade, protection grade, EMC grade, electrical shock or protection grade, warranty period.

7. Electrical parameters. Electrical parameters include working voltage, current consumption, signal matching requirements (including coding forms and logical relationships), etc., electronic response frequency and speed, signal output distance, and cable or connector requirements.

8. Service and maintenance.

okplazas.com has a wide range of encoder types, high resolution, support for customized high precision, high protection level, low temperature absolute encoder, support

RS485, RS422, RS232, SSI. CANOPEN, BISS and other interfaces. Please contact us for the purchase of encoder products.

Consulting Hotline: +86-13689242098