okplazas.com talks about how encoders can become unsung heroes around us

okplazas.com talks about how encoders can become unsung heroes around us

okplazas.com talks about how encoders can become unsung heroes around us

Unsung heroes around us

What is the function of the so-called encoder? Detects the direction, amount, and angle of rotation or horizontal movement of the machine. Indeed, the encoder is only a small part. But it may be used on machines that no one has even thought about. Now, we all know that the encoder is used in conjunction with the motor. There are millions of possibilities in the world, and the combination of an encoder and a motor is only a drop in the ocean, and it has more applications that you would never expect.

Where there is a motor there is an encoder

Did you realize that all the encoder applications introduced so far are related to electricity? For rotating or horizontal movement, in addition to electric motor driving as a power source, oil pressure and air pressure are also used as driving methods. But these hydraulic and pneumatic devices basically do not use encoders.

why? First of all, the motor can be turned on or stopped immediately by the control of the power switch. By controlling the motor voltage and frequency, the number of revolutions can be easily changed. Because these actions have a high response, the motor can be controlled with high precision and speed through the encoder.

If oil pressure is used as the power source, it takes time for the oil pressure to rise (such as a propeller), and it cannot be controlled by an encoder like a motor. It is not only when the propeller starts to move, but when the number of revolutions is to be changed, the propeller cannot respond immediately and can only change slowly. This is because the oil pressure driving the propeller is restricted by the viscosity of the oil and the resistance of the pipeline. The change of oil pressure and the lag of the propeller rotation speed make it extremely difficult to control the rotation speed with the encoder. The same is true for pneumatic equipment.

Now I will share the application case of the encoder with you:

Encoder in the elevator

Those who are familiar with motion control are familiar with encoders. But for those who have not touched the encoder, the encoder is relatively unfamiliar. So the editor takes the elevator that we all ride in our daily life as an example to introduce the function of the encoder. Before the introduction, let's imagine the process of taking the elevator. We pressed the "△▽" button, but after a while the elevator reached our floor and opened the door automatically, and then we entered the elevator. After entering the elevator, we press the button corresponding to the floor. The elevator door closed automatically, transporting us to the corresponding floor, and the elevator door opened again.

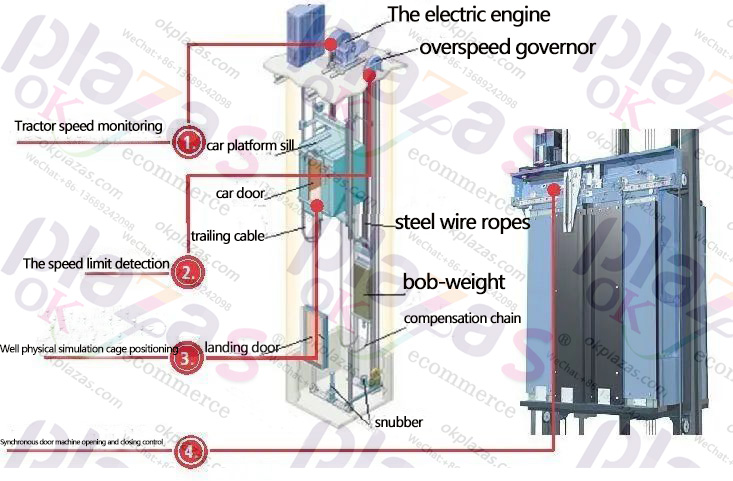

Behind this series of processes, there are actually two encoders that play an important role. I wonder if you noticed it? First, the first encoder performs motor control to move the elevator. Because the elevator moves up and down through the rotation of the motor, as long as the direction of rotation is clear, it can be judged whether the elevator is rising or falling. In addition, the encoder can detect the amount of movement of the motor (number of rotations), so that you can know how much the elevator has moved. Using the information provided by these encoders through the elevator control panel, the elevator can quickly and smoothly reach the designated floor.

The other encoder is a motor that controls the automatic opening and closing of the elevator doors. We often look at the opening and closing of the elevator, we know that there is a delicate and precise control behind it. The timing of the opening of the elevator doors and the timing of the final closing are very accurate. In the process of opening the elevator door, the operation of the elevator door can be accelerated, and the realization time is shortened. Through the encoder to correctly grasp the motor's movement and control it, the silky smooth movement can be realized.

When elevators appeared in people's field of vision, encoders were not yet popular. The above encoder work is all done by humans. There was no "△▽" button at the beginning, and the bell was used. We might be able to see this scene when we watched a movie in the Republic of China. The Shanghai beach boss entered the elevator, and the waiter in the elevator pulled down the gate according to the bell to let the elevator reach the corresponding floor. But now, thanks to the application of encoders that determine the direction of rotation and the number of rotations of the motor, elevators have become more and more convenient and no longer need to be manually operated as before.

Okplazas.com editor recommended brand Applied Motion

Applied Motion Products was founded in 1978, specializing in high-precision, cost-effective motion control products. Provide a complete product portfolio of stepper and servo, drives, motors, controllers, encoders, gearboxes and power supplies to serve various industrial and OEM customer groups.

Part of the encoder product display

01 BAA Encoder

Installed on the rear axle of HT17, HT23 and HT24 stepper motors

• 1000 lines (count after 4000 quadratures per revolution). Other resolutions can be provided on request.

• A, B and Z (index) channels

• Single-ended output

• 5Vdc input voltage

• Use with 3004-362-01 or 3004-363-06 extension cable

• It is not recommended to use with Applied Motion stepper driver to perform stall detection and stall prevention functions.

02 CAA Encoder

• Installed on the rear axle of HT17, HT23 and HT24 stepper motors

• 2000 lines (8000 counts per revolution). Other resolutions can be provided on request.

• A, B and Z (index) channels

• Differential output

• 5 Vdc input voltage

• Use with 3004-329-10 or 3004-349-03 extension cable

03 WAA encoder

• Installed on the rear axle of the HT17 stepper motor

• Wheel diameter 5 mm

• 2000 lines (8000 counts per revolution)

• A, B and Z (index) channels

• Differential output

• 5Vdc input voltage

• Use with 3004-195-10 extension cable

Applied Motion provides a series of powerful standard products to meet your motion control requirements. If your application requires something unusual or unique, Applied Motion can be designed to optimize product performance to meet your needs. The ability to provide customized products can usually bring customers higher productivity and higher reliability, while also reducing costs