The application of Pepperl + Fux photoelectric sensor ML100 series in PCB automatic processing line

The application of Pepperl + Fux photoelectric sensor ML100 series in PCB automatic processing line

The application of Pepperl + Fux photoelectric sensor ML100 series in PCB automatic processing line

There is a very popular test recently: how many episodes can you live in the court? How long can a small photoelectric sensor live in the market without any special skills? This peony country is beautiful and fragrant, and the king of flowers is indeed not for everyone.

The ML100 series of Pepperl+Fuchs Optoelectronics series is the outstanding one among the photoelectric sensors. Today we will introduce it. This is a good "tool" in the "workman's desire to do well, must first sharpen its tools". The use in the line is even more brilliant!

From the emergence of the concept of printed circuits in 1936 to the small-scale PCB production in the early 1950s, after decades of development, PCB has developed into a global industry. PCB equipment refers to all kinds of production and testing equipment used in the production process of PCB, such as board placement machine, rewinding machine, flipping machine, stacking machine, transmission equipment, etc. Are you facing multiple challenges-PCB boards are porous and slotted? The PCB board color is complicated? Have a background to block? Can't it interfere with the camera's photo effect? Are there any more questions? Just throw it over.

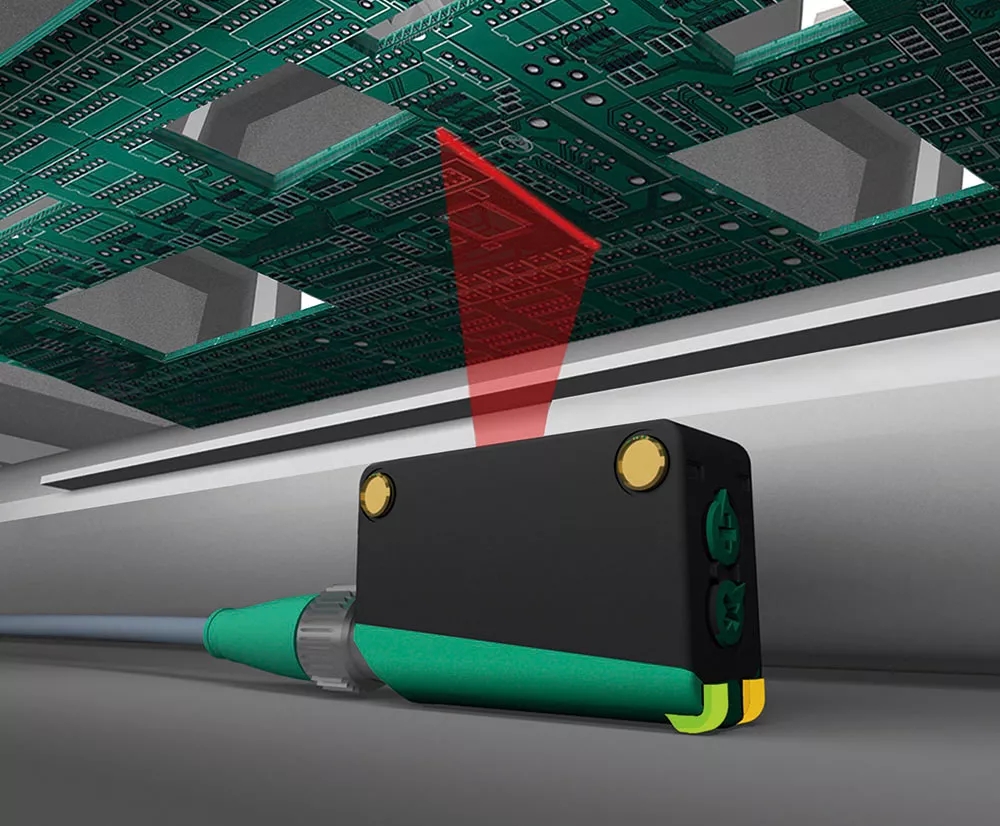

Pepperl+Fuchs proposed that special PCB inspection automation equipment is an indispensable bridge between different processes as early as 10 years ago. In the entire SMT process, including screen printing, placement, reflow soldering, inspection, etc., PCB board inspection Throughout, such as the presence or absence of PCB, PCB in place, etc. PCB boards are porous and multi-slotted, with different colors and materials. The stable and reliable detection of PCB boards poses a higher challenge to the photoelectric switch. Pepperl+Fuchs ML100 series focused narrow and long spot design perfectly meets the needs of the market and meets all your expectations...

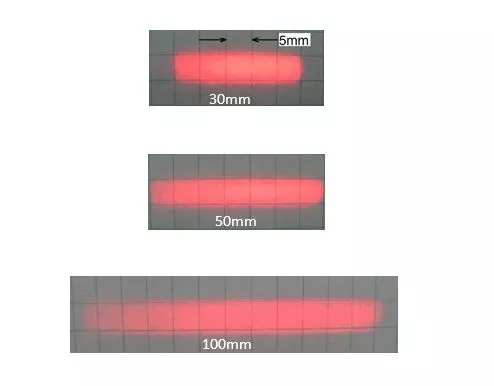

Countermeasure 1: The ML100 long-spot photoelectric series has ultra-high performance and can be used freely. The compact photoelectric ML100 series has a wide range of applications, such as: the inspection of goods in the packaging industry, the sorting of luggage in the logistics industry, and the positioning of targets in the electronics industry. The ML100 series has won the favor of customers with its super high performance and moderate price. The detection distance of ML100-8-HGU-100-RT long spot product is adjustable, the maximum detection distance is 100mm, and the spot size at 100mm is 6mmX60mm.

Countermeasure 2: ML100 infrared light series invisible hero, stable protection In addition to red light products, Pepperl+Fuchs closely followed the market demand and developed the infrared light long spot product ML100-8-HGU-100-IR. In various PCB inspection equipment, such as AOI inspection, appearance inspection, solder paste inspection, etc., visual photography and imaging have become an indispensable step. The red light source will affect the imaging effect, because the newly developed infrared light products become the best option for visual inspection equipment.