What are the structural features and advantages of plum coupling

What are the structural features and advantages of plum coupling

What are the structural features and advantages of plum coupling?

The quincunx-shaped elastic coupling utilizes quincunx-shaped elastic elements to be placed between the two halves of the coupling claws to realize the coupling of the two halves of the coupling. It has the characteristics of compensating the relative displacement of the two shafts, damping, buffering, small radial size, simple structure, no lubrication, high carrying capacity, convenient maintenance, etc.

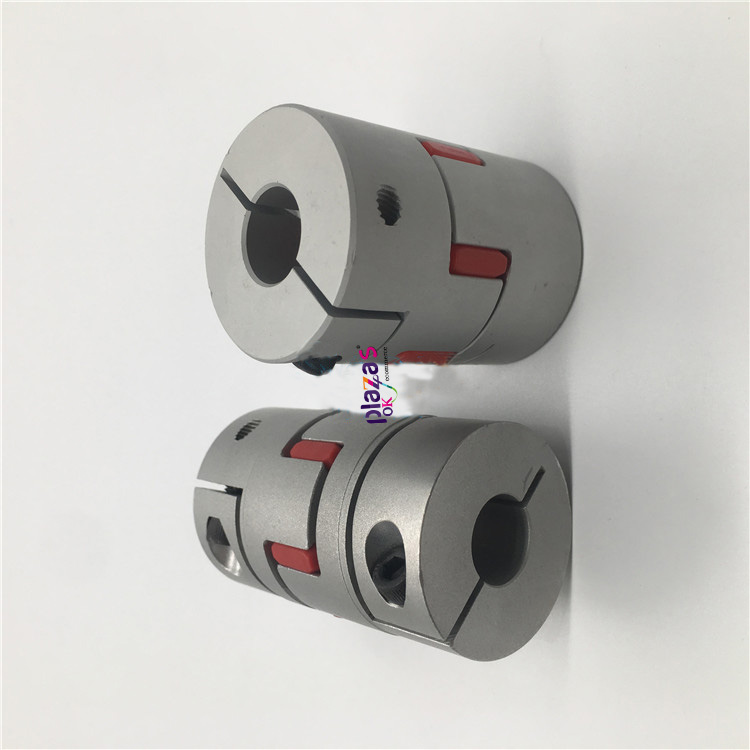

The plum-shaped elastic coupling is a widely used coupling, also called a claw coupling, which is composed of two metal claw discs and an elastic body. The two metal claws are generally made of No. 45 steel, but aluminum alloys are also useful when load sensitivity is required. The elastic element of the plum blossom coupling is similar to the plum blossom shape, and the replacement of the elastic element requires axial movement (except for LMD and LMS types). There are two types of quincunx elastic elements: polyurethane and cast nylon. There are mainly four petals, six petals, eight petals, ten petals and twelve petals. MT1: four petals, MT2-MT7 six petals, MT8-MT9: eight petals, MT10-MT12: ten petals, MT13-MT14: twelve petals.

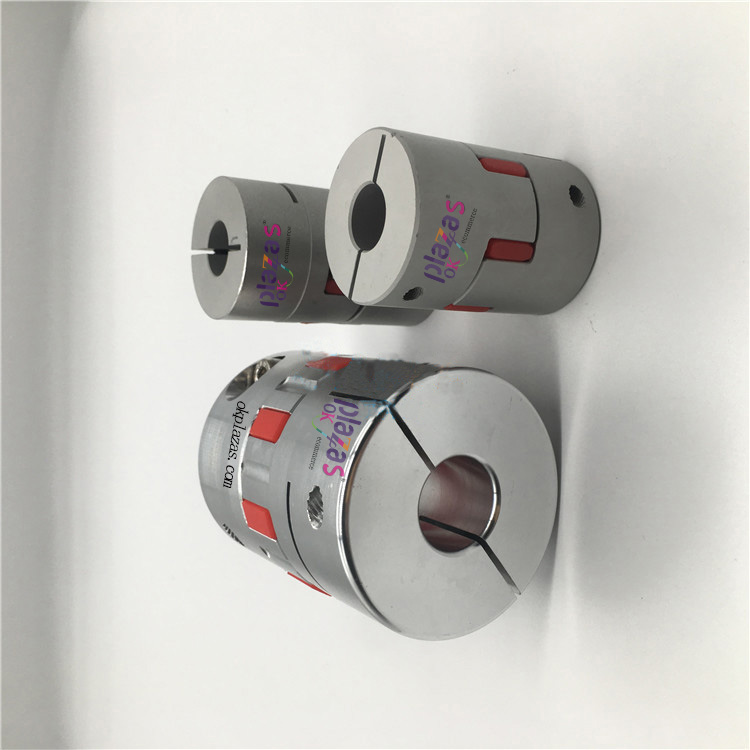

The structure of plum coupling mainly includes basic type, single flange type, double flange type, split brake wheel type, and integral brake wheel type. The quincunx-shaped elastic coupling is composed of two half-couplings with the same shape of the claws and elastic elements. The quincunx-shaped elastic element is placed between the two halves of the coupling claws to realize the coupling of the two halves. Join.

What are the structural features and advantages of plum coupling?

Compared with other couplings, the plum blossom coupling has the following advantages:

(1) Stable and reliable work, with good vibration damping, buffering and electrical insulation properties.

(2) Simple structure, small radial size, light weight, small moment of inertia, suitable for medium and high speed occasions.

(3) It has large axial, radial and angular compensation capabilities.

(4) High-strength polyurethane elastic elements are wear-resistant and oil-resistant, have large carrying capacity, long service life, and are safe and reliable.

(5) The coupling does not need lubrication, the maintenance workload is small, and it can run continuously for a long time.

What are the structural features and advantages of plum coupling?

There are two main types of plum blossom couplings, one is the traditional straight claw type, and the other is the curved (concave) claw type zero-backlash coupling. The traditional straight-jaw type plum blossom coupling is not suitable for high-precision servo transmission applications. The zero-backlash claw type plum blossom coupling evolved on the basis of the straight claw type, but the difference is that its design can be adapted to the application of the servo system, and is often used to connect servo motors, stepping motors and ball screws. The curved surface is to reduce the deformation of the elastic plum spacer and limit the influence of centripetal force on it during high-speed operation. The zero-clearance claw coupling is composed of two metal sleeves (usually made of aluminum alloy, stainless steel can also be provided) and a plum blossom elastic spacer.

What are the structural features and advantages of plum coupling?

The plum blossom elastic spacer has multiple leaf branches. Like a slider coupling, it also squeezes the plum blossom elastic spacer and the sleeves on both sides to ensure its zero clearance performance. Unlike the slider coupling, the plum blossom coupling is driven by squeezing while the slider coupling is driven by shear. When using a zero-clearance claw coupling, the user must be careful not to exceed the maximum bearing capacity of the elastic element given by the manufacturer. The plum blossom coupling has a good balance performance and is suitable for high-speed applications (the maximum speed can reach 30,000 rpm), but it cannot show large deviations, especially axial deviations. Larger eccentricity and deflection angle will produce larger bearing load than other servo couplings.