What are the structure and operating characteristics of the diaphragm coupling

What are the structure and operating characteristics of the diaphragm coupling

What are the structure and operating characteristics of the diaphragm coupling?

What are the structure and operating characteristics of the diaphragm coupling?

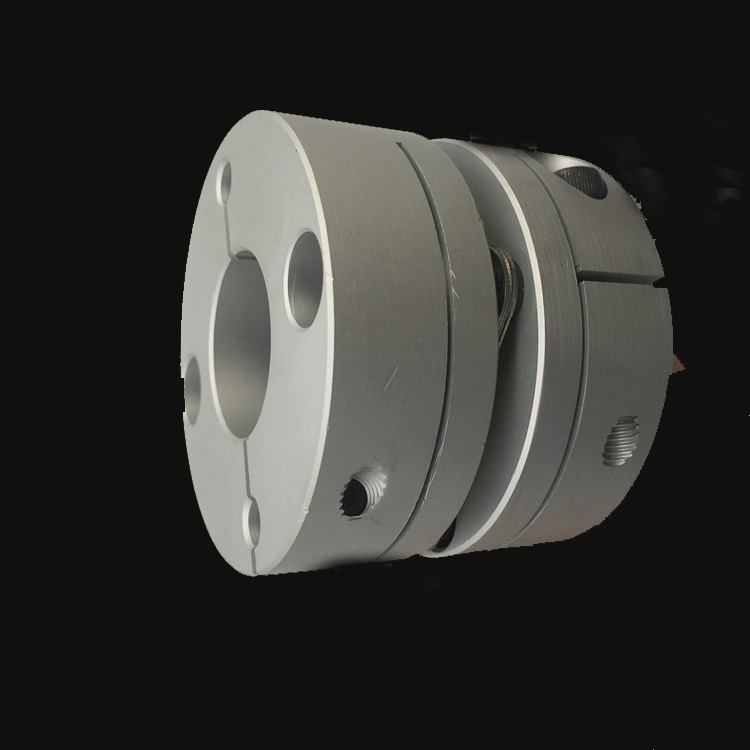

The structure of the diaphragm coupling is to cross-fix the diaphragm group with two halves of the coupling with bolts. The diaphragm coupling is composed of at least one diaphragm and two shaft sleeves. The diaphragm is fastened to the sleeve with a pin and generally will not loosen or cause backlash between the diaphragm and the sleeve. Some manufacturers provide two diaphragms, and others provide three diaphragms, with one or two rigid elements in the middle, and the two sides are connected to the shaft sleeve. The difference between the single diaphragm coupling and the double diaphragm coupling is the ability to handle various deviations. In view of the complex bending of the diaphragm, the single diaphragm coupling is not suitable for eccentricity. The double diaphragm coupling can bend in different directions at the same time to compensate for eccentricity.

Structure characteristics of diaphragm coupling

The characteristics of diaphragm couplings are a bit like bellows couplings. In fact, the way couplings transmit torque is similar. The diaphragm itself is very thin, so it is easy to bend when the relative displacement load is generated, so it can withstand up to 1.5 degrees of deviation, while generating a lower bearing load in the servo system. Diaphragm couplings are often used in servo systems. Diaphragms have good torque rigidity, but are slightly inferior to bellows couplings. On the other hand, the diaphragm coupling is very delicate and can be easily damaged if it is misused in use or not installed correctly. Therefore, it is very necessary to ensure that the deviation is within the tolerance range of the normal operation of the coupling. Choosing the right coupling is a key step to make good use of the coupling. You have to consider what type of coupling to choose in the design stage. Compared with the gear coupling, the coupling has no relative sliding, no lubrication, sealing, no noise, basically no maintenance, easy to manufacture, and can partially replace the gear coupling. Diaphragm couplings are commonly used in developed countries in the world. Machinery industry standards have been formulated in our country, and they have recently been revised into new industry standards: JB/T 9147-1999 (instead of ZB/T J19022-90) The relationship between each torque of the device.

What are the structure and operating characteristics of the diaphragm coupling?

The structure of the diaphragm coupling is to connect the diaphragm group to the two halves of the coupling with bolts. The bolt holes are divided into 4 holes, 6 holes, 8 holes, 10 holes, and 12 holes. The form of the diaphragm is divided into continuous polygonal ring, circular ring, separated connecting rod shape, spoke shape, formed diaphragm and waved diaphragm.

1. Diaphragm form: continuous polygonal ring shape, circular ring shape, separate connecting rod shape, spoke shape, formed diaphragm, waved diaphragm.

2. The characteristics of continuous polygonal ring and circular ring: Each coupling is composed of several diaphragms of equal thickness. The outer edge of each piece is arc-shaped, which has better elasticity, simple shape, convenient processing, but poor elasticity. In addition, the elasticity with a small number of sides is better than the elasticity with a large number of sides, but if the number of sides is too small, the stability will also be reduced. When one-way operation is performed, only half of the ring sides carry the transfer torque.

3. Separate connecting rod shape feature: Each diaphragm is composed of a separate thin rod to form a polygon. The rod shape is simple and easy to manufacture, but requires precise hole spacing. Its performance is basically the same as that of a continuous polygon ring, but the strength and speed are Low, suitable for occasions where the coupling size is restricted.

4. The characteristics of the spoke shape: Each coupling is composed of several pieces. The screw holes on the outer edge and the inner edge are respectively connected with the driving and driven half couplings, which are twisted during operation. The formed holes on the diaphragm are In order to increase the elasticity, the difference between the inner and outer diameters should not be too small due to elasticity, and it is generally appropriate to transmit medium and small power.

5. The characteristics of the formed diaphragm: Each coupling is composed of a single diaphragm. The thickness of the diaphragm decreases regularly from the inner to the outer hyperbola to maintain the same strength conditions. The material utilization rate is high and the integrity is good. It is suitable for high-speed transmission, but the manufacturing precision of the diaphragm is higher.

6. The characteristics of the corrugated diaphragm: The diaphragm is corrugated in the axial section, with high flexibility and good compensation performance.

The thickness of the diaphragm coupling has a single-piece hyperbolic type with equal thickness and unequal thickness, which has better performance and is currently used in many applications.

What are the structure and operating characteristics of the diaphragm coupling?

1. Do not lubricate the diaphragm coupling and require no maintenance; it can fundamentally eliminate the vibration of the gear coupling due to tooth surface wear; avoid a series of troubles such as a new imbalance of the gear coupling due to oil accumulation problem.

2. It can be assembled and disassembled without interfering with the master-slave device. The replacement of the coupling can be completed within 2 hours, which improves equipment utilization.

3. It can operate under harsh environmental conditions, can operate within 300 degrees Celsius, and can operate under corrosive environments such as acid, alkali, and salt spray.

4. Strong ability to withstand misalignment, with a certain ability to reduce vibration and noise. Misalignment can meet the misalignment requirements of most power transmission devices in operation.

5. Zero clearance, constant low unbalance, and noiseless coupling parts adopt gapless assembly, no running noise, and maintain the same initial dynamic balance accuracy.

6. Applying predictable low additional load to the connected device Compared with similar flexible transmission elements, the diaphragm coupling exerts the smallest predictable force and bending moment on the connected device.

7. With high power-to-mass ratio, it is especially suitable for connecting high-power power devices.

8. The non-linear change of the stiffness between the diaphragm coupling shafts effectively restricts the drift of the magnetic center of the motor.